Initial Time of Set of Fresh Concrete

Initial Time of Set of Fresh Concrete – Use this method to determine the initial time-of-set of fresh retarded concrete in the field.

This method describes a procedure that uses a penetration resistance apparatus and the mortar fraction of the concrete.

The values given in parentheses (if provided) are not standard and may not be exact mathematical conversions.

Use each system of units separately. Combining values from the two systems may result in nonconformance with the standard.

DEFINITION

Initial Time of Set of Fresh Concrete —Initial time of set is the elapsed time after initial contact of cement and water required for sieved mortar to reach a penetration

resistance of 3.5 MPa (500 psi).

This definition is according to ASTM C 403 and AASHTO T 197.

Note 1—Since the setting of concrete is a gradual process, any definition of time of setting must necessarily be arbitrary.

In this test method, the time required for mortar to reach a penetration resistance of 3.5 MPa (500 psi) defines the initial time of set

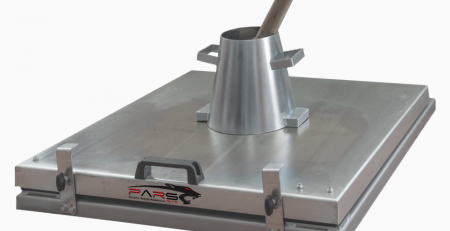

APPARATUS

Concrete mortar penetrometer, penetration resistance apparatus meeting the requirements

Sieve, 4.75 mm (No. 4).

Containers, rigid, watertight, non-absorptive, non-oiled and either cylindrical or rectangular in cross-section.

The minimum lateral dimension shall be 152 mm (6 in.) and the height at least 152 mm (6 in.). A beam mold is a suitable container.

Tamping rod,

Thermometer

PROCEDURES

Preparing Mortar Specimen

From the concrete mixture under test, select a representative sample of sufficient volüme to provide enough mortar to fill the test container to a depth of at least 140 mm (5-1/2 in.).

Remove all the mortar from the sample of concrete by sieving it through a 4.75 mm

(No. 4) sieve onto a non-absorptive surface. Remix the mortar and place it in the container in a single layer.

Consolidate the mortar by rodding. Rod once for each 645 mm2 (1 in.2 ) of top surface area, then tap the sides of the container with the tamping rod to close all voids.

Determining Initial Time of Set of Fresh Concrete

The time for initial penetration test will depend on the conditions of the mix and weather.

When expecting extended retardation, observe the specimen to catch the beginning of the stiffening process, which may occur four to eight hours after adding the water to the mix.

When the specimen begins to stiffen (a slight resistance to thumb pressure), make the initial penetration tests.

To make the penetration test, bring the bearing surface of the penetrometer needle in contact with the mortar surface.

Apply a vertical force downward on the apparatus gradually and uniformly, until the needle penetrates the mortar to a depth of 25.4 mm (1 in.) as indicated by the scribe mark.

Approximately 10 seconds is required to penetrate to the 25.4 mm (1 in.) depth.

Make penetration resistance determinations at 15-30 minute intervals, until reaching one penetration resistance of at least 3.5 MPa (500 psi).

Make at least six penetrations throughout the time-of-setting test.

In making penetrations, take care to avoid areas where the mortar has been disturbed by previous tests.

The clear distance between impressions should be at least 19 mm (3/4 in.).

The clear distance between any needle impression and the sides of the container should be at least 25.4 mm (1 in.).

Record the pressure required and the time (elapsed time since water was added to mix) of penetration.

Plot the results showing penetration resistance as the ordinate and the elapsed time as the abscissa.

Read the initial time-of-set at 3.5 MPa (500 psi) from the plotted curve.

Record the initial temperature of concrete near the embedded cone and the ambient temperature during the test period.

Leave a Reply

You must be logged in to post a comment.