Los Angeles Abrasion Test

Los Angeles Abrasion Test

The abrasion test of aggregate on aggregates is done for the following purposes:

To find out the Los Angeles abrasion value of aggregate.

To find the suitability of aggregates for use in road construction projects.

Apparatus used for Abrasion Test

The apparatus is standardized as per IS: 2386 (Part IV) – 1963 consists of:

Los Angeles abrasion machine

Abrasive charge balls: Cast iron or steel balls, approximately 48mm in diameter and each weighing between 390 to 445 gm; six to twelve balls are required

Sieve: 1.70mm , 2.36mm, 4.75mm, 6.3mm, 10mm, 12.5mm, 20mm, 25mm, 40mm, 50mm, 63mm, 80mm IS Sieves.

The balance of capacity 5 kg or 10 kg is used.

Oven Drying.

Miscellaneous elements like a tray.

Los angeles Abrasion Test Procedure

The aggregates sample consists of clean aggregates dried in an oven at 105° – 110°C.

The aggregates sample should conform to any of the grading shown in the below table.

Select the size of aggregate to be used in the test such that it conforms to the grading to be used in construction, to the maximum extent possible.

Take exactly 5 kg of the sample for grades A, B, C & D, and 10 kg for grading E, F & G.

Choose the abrasive charge balls as per Table 2 depending on the grading of aggregates.

Place the aggregates and abrasive charge balls on the cylinder and fix the cover.

After that Rotate the machine at a speed of 30 to 33 revolutions per minute.

The number of revolutions should be 500 for grades A, B, C & D and 1000 for grading E, F & G.

The machine is stopped after the specified number of revolutions and the aggregate sample is discharged to a tray.

The entire stone dust made from a machine is sieved on 1.70 mm IS sieve.

The material size more than 1.7 mm size is weighed correct to one gram.

Observations

The original weight of aggregate sample = W1 g

The weight of the aggregate sample retained = W2 g

Weight sample passing 1.7mm IS sieve = W1 – W2 g

Abrasion Value = (W1 – W2 ) / W1 X 100

Sample Calculation

Let the weight of the aggregate be W1 = 5000 gram

Weight of the aggregate sample retained W2 = 2100 gram

Weight sample passing 1.7mm IS sieve = W1 – W2 g = 2900 gram

Abrasion Value = (W1 – W2 ) / W1 X 100 = (2900/50000) X 100 = 58

Results

Los Angeles Abrasion Value of Aggregate = 58

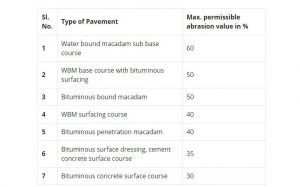

IS Recommended Los Angeles Abrasion Value of Aggregate for Pavements

A Los Angeles test is performed to find the hardness of aggregates. On the basis of this value, the suitability of aggregates for different road constructions

can be judged as per IRC specifications as given,

Conclusion

Following the Los Angelos Abrasion Test as mentioned above, we derived the abrasion value of the sample as 58.

From the table given above, the suitability of aggregates used for the pavements can be known.

For the sample calculation that was done here having an abrasion value of 58, the aggregates can be employed only for the WBM sub-base course.

Its maximum permissible abrasion value is 60.

Leave a Reply

You must be logged in to post a comment.