ASTM A48 – Standard Specification for Gray Iron Castings

ASTM A48 Tensile Testing Gray Iron Castings

ASTM A48 – This specification covers gray iron castings intended for general engineering use where tensile strength is a major consideration.

*** This specification subordinates chemical composition to tensile strength.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM A48 – Standard Specification for Gray Iron Castings

ASTM A48 Tensile Testing Gray Iron Castings

ASTM A48 – This specification covers gray iron castings intended for general engineering use where tensile strength is a major consideration.

Castings are classified on the basis of the tensile strength of the iron in separately cast test bars.

*** This specification subordinates chemical composition to tensile strength.

Castings produced to this specification are graded on the basis of minimum tensile strength obtained in special test coupons designed to standardize cooling rate.

The tensile strength developed in certain casting sections may vary from test coupon values (see X1.2).

This specification covers gray iron castings intended for general engineering use where tensile strength is a major consideration.

Castings are classified on the basis of the tensile strength of the iron in separately cast test bars.

The surface of the casting shall be free of adhering sand, scale, cracks, and hot tears, as determined by visual examination.

The test bars are designated into S, A, B, and C categories, according to the thickness of its controlling wall section.

The casting shall be subjected to a tension test to determine its tensile strength.

Gray iron does have several drawbacks including low tensile strength and the inability for it to be worked. The class rating for this metal are based on the

tensile strength.

Class No. 20 is 20+ ksi, class 25 is 25, class 300 is 300ksi, etc.

Geometry

There are three sizes of cast metal tensile bars for this test.

The main difference between sample types is the diameter which is either at .5″, .75″, or 1.25″.

The radius of the fillet is different for the largest sample. The specimens are button head type and the test bars are cast separately.

Analysis

ASTM A84 provides a simple measure of ultimate tensile strength.

The tensile strength is calculated by taking the peak load and dividing it by the square area of the sample.

For .5″ diameter samples, the square area is .25.

Similar Specifications

ASTM E8 – Metal Tensile Testing

ASTM A370 – Steel Tensile Testing

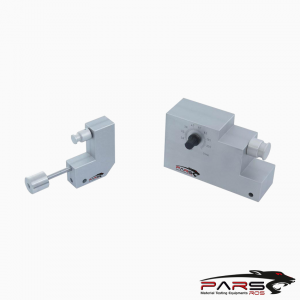

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests that are

accurate and repeatable.

TECHNICAL SPECIFICATIONS

Please contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations