ASTM C1292 Test Fikstürü

ASTM C1292 covers the determination of shear strength of continuous fiber-reinforced ceramic composites (CFCCs) at ambient temperature.

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- Değerlendirmeler (0)

- TEKNİK ÖZELLİKLER

Açıklama

Açıklama

ASTM C1292 / Standard Test Method for Shear Strength of Continuous Fiber-Reinforced Advanced Ceramics at Ambient Temperatures

ASTM C1292 covers the determination of shear strength of continuous fiber-reinforced ceramic composites (CFCCs) at ambient temperature.

The test methods addressed are (1) the compression of a double-notched specimen to determine interlaminar shear strength and (2) the Iosipescu test

method to determine the shear strength in any one of the material planes of laminated composites.

Specimen fabrication methods, testing modes (load or displacement control), testing rates (load rate or displacement rate), data collection, and reporting

procedures are addressed.

ASTM C1292 / This test method is used for testing advanced ceramic or glass matrix composites with continuous fiber reinforcement having uni-directional

(1-D) or bi-directional (2-D) fiber architecture.

This test method does not address composites with (3-D) fiber architecture or discontinous fiber-reinforced, whisker-reinforced, or particulate-reinforced ceramics.

ASTM C1292 / Summary of Test Method

ASTM C1292 addresses two methods to determine the shear strength of CFCCs: (1) the compression of a double-notched specimen test method to determine

interlaminar shear strength9 and (2) the Iosipescu test method to determine the shear strength in any one of the material planes of laminated CFCCs.10

Shear Test by Compression Loading of DoubleNotched Specimens

The interlaminar shear strength of CFCCs, as determined by this method is measured by loading in compression a double-notched specimen of uniform width.

Failure of the specimen occurs by shear between two centrally located notches machined halfway through the thickness and spaced a fixed distance apart

on opposing faces.

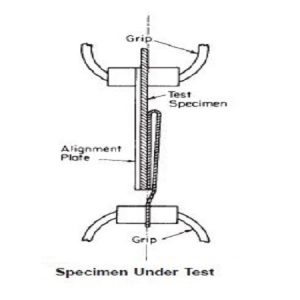

Shear Test By the Iosipescu Method

The shear strength of one of the different material shear planes of laminated CFCCs may be determined by loading a coupon in the form of a rectangular flat strip

with symmetric centrally located V-notches using a mechanical testing machine and a four-point asymmetric fixture

Failure of the specimen occurs by shear between the V-notches. Different specimen configurations are addressed for this test method. Schematics of the test setup.

The determination of shear properties of polymer matrix composites by the Iosipescu method has been presented in Test Method D 5379

Apparatus

Testing Machines

The testing machine shall be in conformance with Practices E 4.

The loads used in determining shear strength shall be accurate within 61 % at any load within the selected load range of the testing machine as defined in

Practices E 4.

Test Fixtures

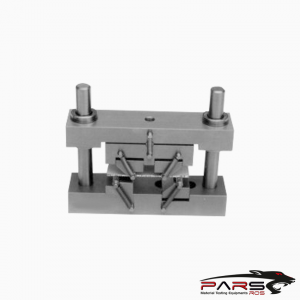

Double-notched Compression Specimen

The fixture consists of a stationary element mounted on a base plate, an element that attaches to the crosshead of the testing machine, and two jaws to fix the

specimen in position.

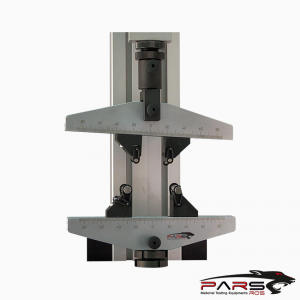

Losipescu Specimen

The fixture shall be a four-point asymmetric flexure fixture

This fixture consists of a stationary element mounted on a base plate, and a movable element capable of vertical translation guided by a stiff post.

The movable element attaches to the cross-head of the testing machine.

Each element clamps half of the test specimen into position with a wedge action grip able to compensate for minor specimen width variations.

A span of 13 mm is left unsupported between fixture halves.

An alignment tool is recommended to ensure that the specimen notch is aligned with the line-of-action of the loading fixture.

*** Before conducting ASTM C1292 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Değerlendirmeler (0)

“ASTM C1292 Test Fikstürü” için yorum yapan ilk kişi siz olun

Değerlendirme yazabilmek için oturum açmalısınız.

Değerlendirmeler

Henüz değerlendirme yapılmadı.