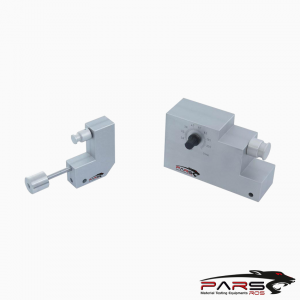

ASTM C1404 Test Fixture

ASTM C1404 covers the laboratory determination of the bond strength of adhesive systems used to adhere freshly mixed mortar to hardened portland-cement concrete.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM C1404 – Standard Test Method for Bond Strength of Adhesive Systems Used With Concrete as Measured by Direct Tension

ASTM C1404 covers the laboratory determination of the bond strength of adhesive systems used to adhere freshly mixed mortar to hardened portland-cement concrete.

ASTM C1404 / Significance and Use

The bonding properties of adhesives are important for concrete repair applications.

This test method provides a means to measure the adhesive characteristics of materials used to bond freshly mixed mortar to hardened concrete.

In addition to providing information on bond strength, the location of failure is determined visually and is thus instructive regarding the weakest element in the

composite tested.

The bond strength that is measured is limited by the tensile strength of the base concrete and mortar.

While an attempt has been made to choose materials that are strong enough to force a bond failure, there may be cases where failure occurs in concrete or mortar.

In these situations, the actual bond strength exceeds the measured result.

ASTM C1404 /Apparatus

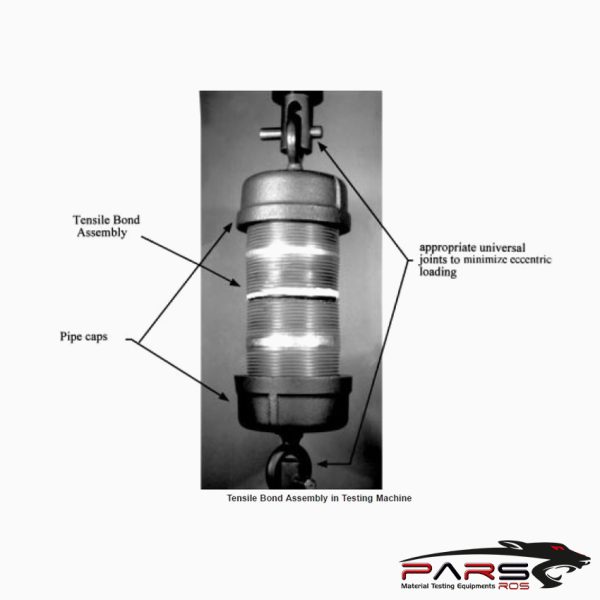

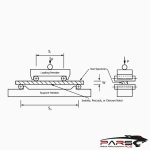

ASTM C1404 / Testing Machine—The testing machine shall be of the hydraulic or screw-type and capable of measuring tensile loads up to 5000 lbf [22 kN]

in increments of 45 lbf [200 N] at rates

Steel-Pipe Nipples—The steel-pipe nipples shall conform to Specification A 333/A 333M, be nominally 3 in. [75 mm] in diameter by 3 in. [75 mm] long Schedule 40,

threaded; two per specimen.

The inside surface of the steel-pipe nipples shall be clean and free of oil or other contaminants that could inhibit bond.

The inside surface shall be sandblasted to gray metal condition.

Steel-Pipe Cap—Two steel-pipe caps nominally 3 in. [75 mm] in diameter, and threaded to fit the steel-pipe nipple molds.

Each cap shall be fitted with a steel rod or eye bolt with at least one universal joint for connection to the testing machine.

The assembly shall have a tensile capacity of at least 5000 lbf [22 kN].

Referenced Documents

ASTM A 333/A 333M Specification for Seamless and Welded Steel Pipe for Low-Temperature Service

ASTM C33 Specification for Concrete Aggregates

ASTM C39 Test Method for Compressive Strength of Cylindrical Concrete Specimens

ASTM C42 Test Method for Obtaining and Testing Drilled Cores and Sawed Beams of Concrete

ASTM C109 Test Method for Compressive Strength of Hydraulic Cement Mortars using 2-in. [50 mm] Cube Specimens

ASTM C150 Specification for Portland Cement

ASTM C171 Specification for Sheet Materials for Curing Concrete

ASTM C192 Practice for Making and Curing Concrete Specimens in the Laboratory

ASTM C305 Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency

ASTM C494 Specification for Chemical Admixtures for Concrete

ASTM C881 Specification for Epoxy-Resin-Base Bonding Systems for Concrete

ASTM C670 Practice for Preparing Precision Statements for Test Methods for Construction Materials

*** Before conducting ASTM C1404 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Reviews (0)

Be the first to review “ASTM C1404 Test Fixture”

You must be logged in to post a review.

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Reviews

There are no reviews yet.