ASTM C1425 Test Fixture

ASTM C1425 is used for calculating the Interlaminar shear strength of advanced ceramic with continuous fiber reinforcement

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM C1425 – StandardTest Method for Interlaminar Shear Strength of 1–D and 2–D Continuous Fiber-Reinforced Advanced Ceramics at Elevated Temperatures

ASTM C1425 is used for calculating the Interlaminar shear strength of advanced ceramic with continuous fiber reinforcement having a laminated structure such as

in unidirectional (1D) or bidirectional (2D) fiber architecture.

This test method is not used for composites with non-laminated structures, such as (3D) fiber architecture or discontinuous fiber-reinforced, whisker reinforced

or particulate-reinforced ceramics.

This test is used for material development, material comparison, quality assurance, characterization, and design data generation of advanced ceramics.

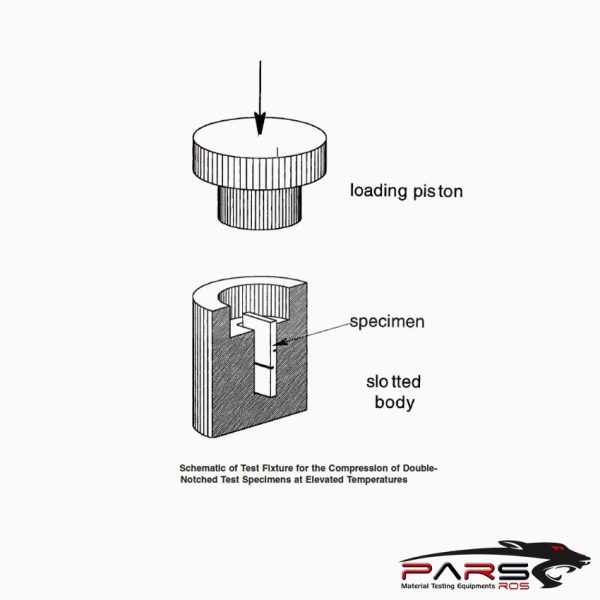

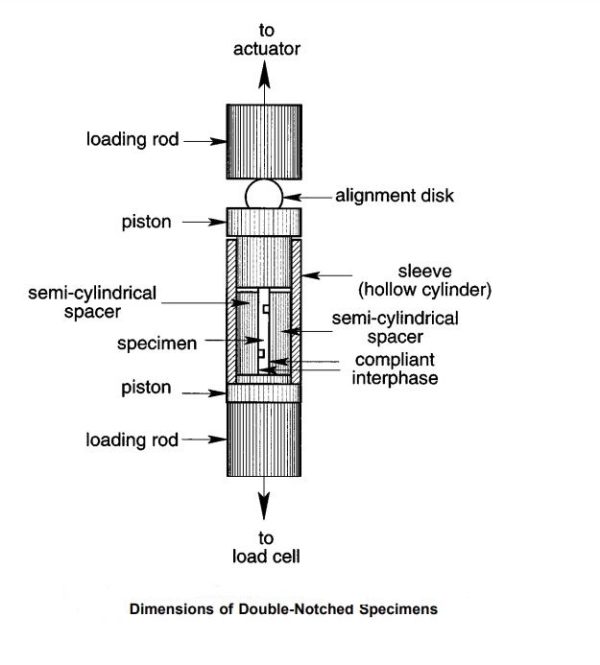

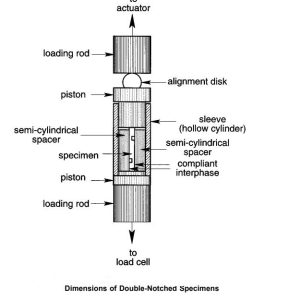

Test Procedure

The test procedure for ASTM C1425 begins with measuring the dimensions of the specimen.

The specimen is mounted. Specimens with different grip interfaces and specimen geometry are mounted differently in the load train.

Thermocouples are positioned to measure and control the temperature during the test.

The test mode and test rate are selected on the test machine. The specimen is preloaded to remove the “slack” from the load train, and the amount of preload

used is reported. The amount of preload for each situation is specific to each specimen geometry.

The data acquisition and test mode are initiated.

The furnace heating is initiated.

The specimen is heated until it reaches thermal equilibrium.

In the load train, a constant minimal force is maintained for the thermal expansion of the specimen and the load train.

The Specimen is compressed till fracture.

After that, the test machine and the data acquisition system are disabled. As per ASTM C1425, the breaking load should be measured with an accuracy of

61% of the load range.

The actuator is retracted and the furnace is allowed to cool down. The specimen is carefully removed from the fixture.

ASTM C1425 / Specimen size

In ASTM C1425 testing, the specimens are rectangular plates with notches created on both sides.

The depth of the notches should be at least half of the specimen’s thickness.

The distance between the notches is determined by the requirements of shear failure.

Because the interlaminar shear strength depends on the notch separation, tests are conducted with different values of notch separation to determine this

dependence.

The edges of the specimens should be smooth, not rounded or beveled.

Unless valid results can be obtained through fewer specimens, at least 10 test specimens per test condition are tested.

Referenced Documents

ASTM C1145 Terminology of Advanced Ceramics

ASTM C1292 Test Method for Shear Strength of Continuous Fiber- Reinforced Advanced Ceramics at Ambient Temperatures

ASTM D695 Test Method for Compressive Properties of Rigid Plastics

ASTM D3846 Test Method for In-Plane Shear Strength of Reinforced Plastics

ASTM D3878 Terminology for Composite Materials

ASTM E4 Practices for Force Verification of Testing Machines

ASTM E6 Terminology Relating to Methods of Mechanical Testing

ASTM E122 Practice for Calculating Sample Size to Estimate,With Specified Precision, the Average for a Characteristic of a Lot or Process

ASTM E220 Test Method for Calibration of Thermocouples By Comparison Techniques

ASTM E230 Specification and Temperature-Electromotive Force

ASTM (EMF) Tables for Standardized Thermocouples

ASTM E337 Test Method for Measuring Humidity with a Psychrometer (the Measurement of Wet- and Dry-Bulb Temperatures)

IEEE/ASTM SI 10 American National Standard for Use of the International System of Units (SI): The Modern Metric System

*** Before conducting ASTM C14125 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Reviews (0)

Be the first to review “ASTM C1425 Test Fixture”

You must be logged in to post a review.

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Reviews

There are no reviews yet.