ASTM C1452 Test Fikstürü

ASTM C1452 covers load-bearing and nonloadbearing reinforced autoclaved aerated concrete (AAC) floor, roof, wall, and stair elements used as components

for building construction.

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- Değerlendirmeler (0)

- TEKNİK ÖZELLİKLER

Açıklama

ASTM C1452 Standard Specification for Reinforced Autoclaved Aerated Concrete Elements

ASTM C1452 covers load-bearing and nonloadbearing reinforced autoclaved aerated concrete (AAC) floor, roof, wall, and stair elements used as components

for building construction.

Autoclaved aerated concrete is a cementitous product based on calcium silicate hydrates in which low density is attained by the inclusion of an agent resulting

in macroscopic voids and is subjected to high-pressure steam curing.

Installed units covered by this specification shall be protected against direct exposure to moisture using a coating material accepted by the AAC manufacturer.

The raw materials used in the production of autoclaved aerated concrete are portland cement, quartz sand, water, lime, gypsum or anhydrite, and an agent

resulting in macroscopic voids.

The quartz sand used as a raw material may be replaced by a siliceous fine aggregate other than sand and usually is ground to a fine powder before use.

Fly ash may be used as a sand replacement.

The batched raw materials are mixed together to form a slurry.

The slurry is cast into steel molds. Due to the chemical reactions that take place within the slurry, the volume expands.

After setting, and before hardening, the mass is machine cut with high accuracy into elements of various sizes.

The elements then are steam-cured under pressure in autoclaves where the matrix is transformed into a solid calcium silicate hydrate.

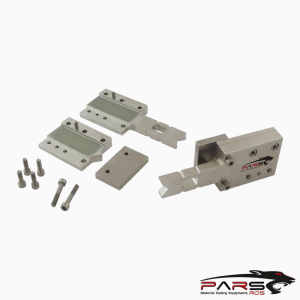

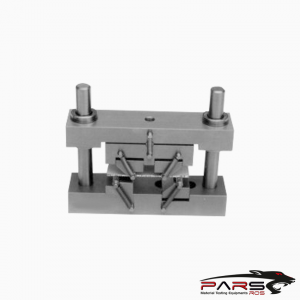

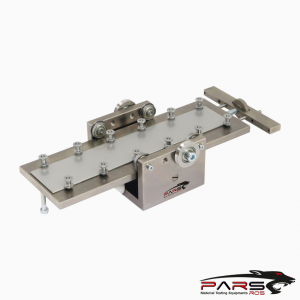

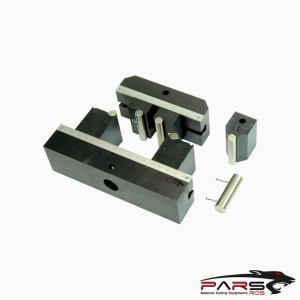

ASTM C1452 / Weld-Point Shear Strength

ASTM C1452 / Apparatus

This test can be performed using the Shear Test Fixture or an equivalent device, which can be fitted into a normal tension testing machine.

Specimen— These specimens should be taken at random from welded reinforcement mats that have not been coated with a corrosionprotection compound.

The bar with the largest diameter shall be selected as the test specimen.

Special test specimens shall not be fabricated for this test except for initial qualification of the welding device.

ASTM C1452 / Procedure—The shear specimen shall be gripped in the test fixture such that the tension bar is centrally located and rotation of the anchoring

bar is prevented.

The loading rate shall not exceed 112 lbf/s (0.5 kN/s).

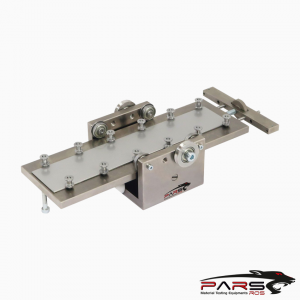

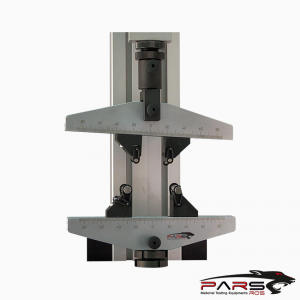

ASTM C1452 / Determination of Transverse Loading (Flexural) Characteristics of AAC Reinforced Elements

Scope—The scope of this test method is to determine the deflection and the load bearing capacity (ultimate load) of these elements.

ASTM C1452 / Apparatus

The testing machine shall allow a service load to be imposed with an accuracy of 5 % and an ultimate load with an accuracy of 2 %.

The testing machine shall be such that the reinforced elements are simply supported on two supports, one fixed and one freely movable in the

horizontal direction, which allows free rotation of the bearing surface, with the bearing surface constructed from steel.

The bearing surface shall provide bearing to the entire width of the element.

The bearing length shall be adjustable, such that the minimum bearing length shall be equivalent to the least bearing length supplied by the manufacturer or

a minimum of 1.6 in. (40 mm).

The deflection gauge shall allow the deflection to be determined with an accuracy of 0.02 in. (0.5 mm).

ASTM C1452 / Test Specimens

The test specimens shall consist of whole AAC reinforced elements as supplied by the AAC manufacturer.

The elements shall not be tested until they have attained the same temperature as the testing environment.

Moisture content of the specimens should be between 10 and 40 % by mass. If the dry density of the AAC material is known to an accuracy of 5 %, then

the moisture content may be determined by calculation based on the mass and volume of the element and the mass of the reinforcement.

The mass of the specimens shall be determined before testing to an accuracy of 10 lb (4.5 kg). Report the moisture content of the AAC at time of test.

ASTM C1452 / Procedure

The load shall be applied as two symmetrical and equal point loads at a distance of one fourth of the clear span from the midspan.

The two-point loads should be transmitted to the surface of the element by steel profiles placed on soft fiberboard with a thickness of 0.4–0.50 in. (10–12 mm).

The steel profiles should have sufficient bearing area to produce an even bearing pressure not exceeding 50 % of the compressive strength of

the AAC material.

The bearing area shall cover the entire width of the element, and its extension along the length of the element shall not be less than 100 mm.

Deflection should be measured at midspan, either on both sides of the element or in the center.

The first deflection reading is taken when the element is resting on the supports without any imposed load.

The loading apparatus is placed in position and load is applied, which corresponds to the imposed service load.

The rate of loading shall be such that the service load is reached after two minutes.

The service load shall be maintained for five minutes during which the element is inspected for cracking.

Should cracks appear, the width shall be measured at a level corresponding to the bottom of the reinforcement.

After the five-minute period of application of the service load is completed, the deflection of the element shall be measured and recorded as the deflection of

the element under the service load.

The element should be loaded to failure with a rate of loading such that the ultimate load is reached after two minutes.

The ultimate load shall be recorded and observations made as to the mode of failure of the specimen.

Before the element is removed from the testing apparatus the number, and size of all of the reinforcement bars shall be recorded as well as the coverage

of the AAC over the steel

*** Before conducting ASTM C1452 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Bir yanıt yazın

Yorum yapabilmek için oturum açmalısınız.