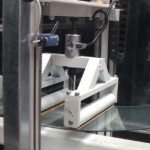

ASTM C203 Test Fixture

ASTM C203 covers the determination of the breaking load and calculated flexural strength of a rectangular cross section of a preformed block-type thermal

insulation tested as a simple beam. It is also applicable to cellular plastics.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM C203 Standard Test Methods for Breaking Load and Flexural Properties of Block

Type Thermal Insulation

ASTM C203 covers the determination of the breaking load and calculated flexural strength of a rectangular cross section of a preformed block-type thermal

insulation tested as a simple beam. It is also applicable to cellular plastics.

Two test methods are described as follows:

Test Method I—A loading system utilizing center loading on a simply supported beam,

Test Method II—A loading system utilizing two symmetric load points equally spaced from their adjacent support points at each end with a distance between load

points of one half of the support span.

1.2 Either test method is capable of being used with the four procedures that follow:

1.2.1 Procedure A— Designed principally for materials that break at comparatively small deflections.

1.2.2 Procedure B— Designed particularly for those materials that undergo large deflections during testing.

1.2.3 Procedure C— Designed for measuring at a constant stress rate, using a CRL (constant rate of loading) machine.

Used for breaking load measurements only.

1.2.4 Procedure D— Designed for measurements at a constant crosshead speed, using either a CRT (constant rate of traverse) or CRE (constant rate of extension)

machine.

Used for breaking load measurements using a fixed crosshead speed machine.

1.3 Comparative tests are capable of being run according to either method or procedure, provided that the method or procedure is found satisfactory for

the material being tested.

1.4 These test methods are purposely general in order to accommodate the widely varying industry practices.

It is important that the user consult the appropriate materials specification for any specific detailed requirements regarding these test methods.

ASTM C203 / Apparatus

ASTM C203 / Testing Machine

A properly calibrated testing machine that is capable of being operated at either constant load rates or constant rates of crosshead motion over

the range indicated, and in which the error in the load-measuring system shall not exceed 61 % of maximum load expected to be measured.

The load-indicating mechanism shall be essentially free of inertial lag.

The accuracy and calibration of the testing machine shall be verified .

If stiffness or deflection measurements are to be made, then the machine shall be equipped with a deflection-type measuring device.

The stiffness of the testing machine shall be such that the total elastic deformation of the system does not exceed 1 % of the total deflection of the test specimen

during test, or appropriate corrections shall be made.

ASTM C203 / Bearing Edges

The loading fittings and supports shall have cylindrical surfaces. In order to avoid excessive indentation, or failure due to stress concentration directly under the

loading fitting or fittings, the diameter of these bearing edges shall be 11⁄4 6 1⁄4 in. (32 6 6 mm).

The bearing cylinders shall be straight and parallel to each other, and they shall be self-aligning to maintain full contact with the specimen throughout the test.

They shall have a length at least equal to the width of the specimen.

*** Before conducting ASTM C203 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Reviews (0)

Be the first to review “ASTM C203 Test Fixture”

You must be logged in to post a review.

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Reviews

There are no reviews yet.