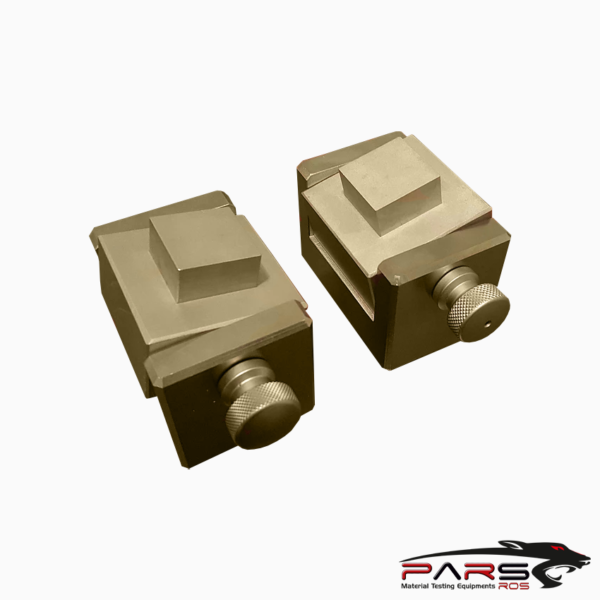

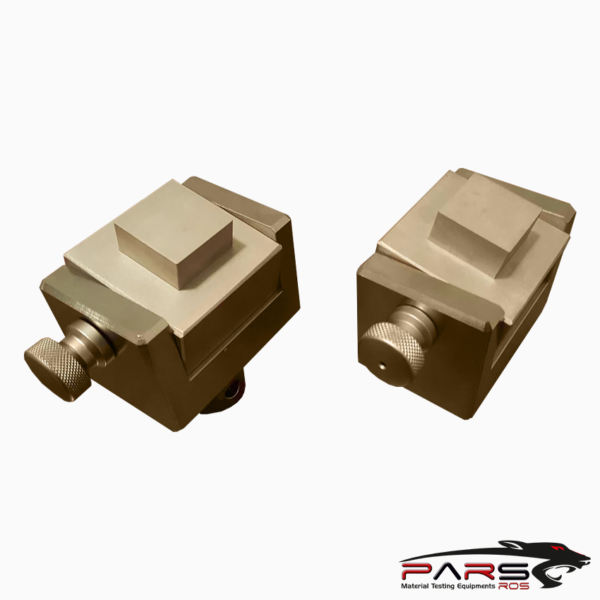

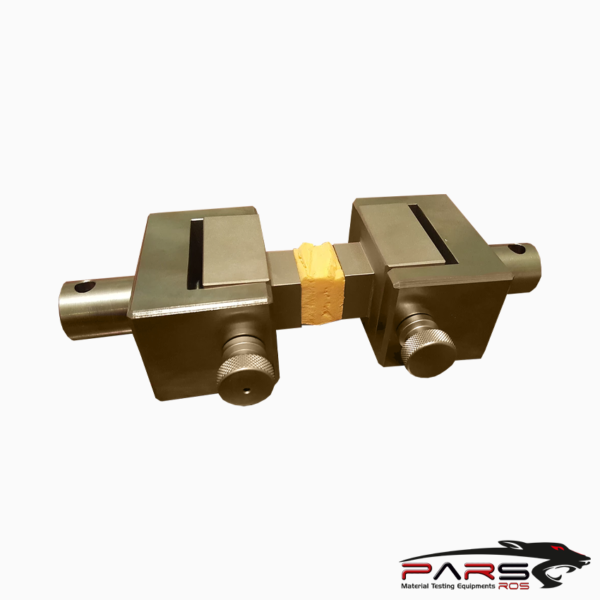

ASTM C297 Test Fixture

ASTM C297 – This test method determines the flatwise tensile strength of the core, the core-to-facing bond, or the facing of an assembled sandwich panel.

Please Contact With Us For More Information

- Description

- TEKNİK ÖZELLİKLER

Description

ASTM C297 – Standard Test Method for Flatwise Tensile Strength of Sandwich Constructions

ASTM C297 – This test method determines the flatwise tensile strength of the core, the core-to-facing bond, or the facing of an assembled sandwich panel.

Permissible core material forms include those with continuous bonding surfaces (such as balsa wood and foams) as well as those with discontinuous bonding surfaces

(such as honeycomb).

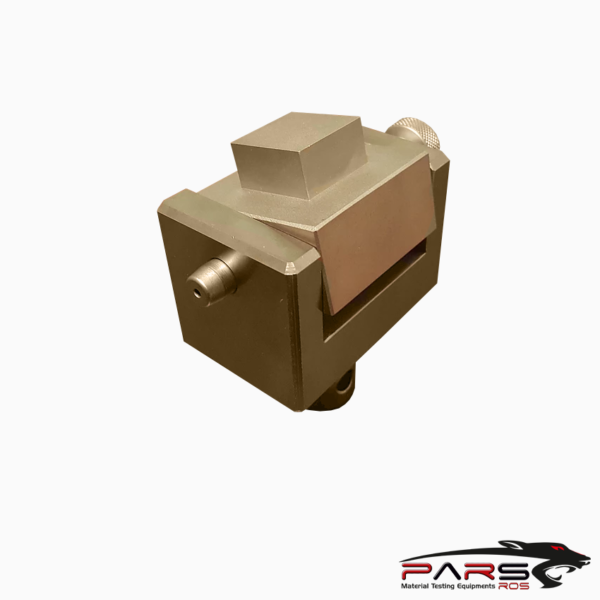

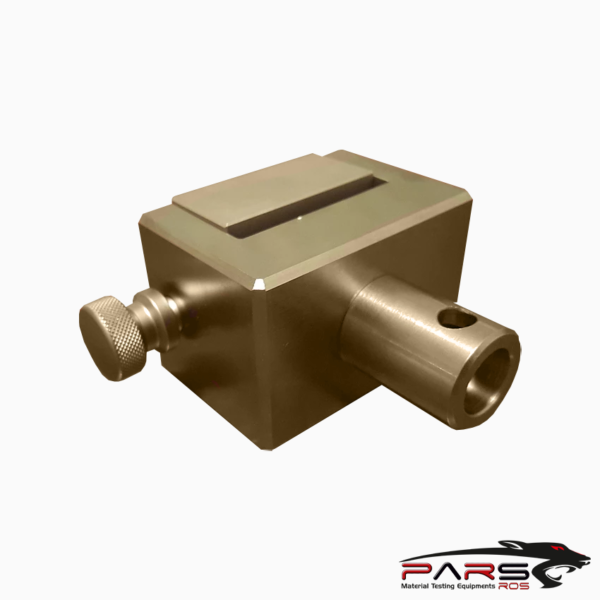

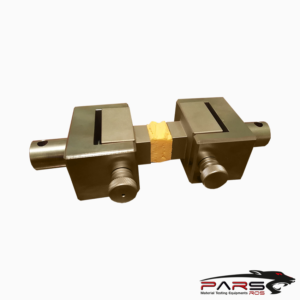

The fixture had a self-aligning mechanism which is designed to provide a 100% uni-axial force. The self-alignment allows for more uniform tensile tests and

measurements to be taken.

ASTM C297 – Summary of Test Method

This test method consists of subjecting a sandwich construction to a uniaxial tensile force normal to the plane of the sandwich.

The force is transmitted to the sandwich through thick loading blocks, which are bonded to thesandwich facings or directly to the core.

The only acceptable failure modes for flatwise tensile strength are those which are internal to the sandwich construction.

Failure of the loading block-to-sandwich bond is not an acceptable failure mode.

ASTM C297 – Loading Fixtures

The loading fixtures shall be self- aligning and shall not apply eccentric loads.

The loading blocks shall be sufficiently stiff to keep the bonded core or facings essentially flat under load. Loading blocks 40 to 50 mm [1.5 to 2.0 in.] thick have been

found to perform satisfactorily.

ASTM C297 – Testing Machine

Testing Machine Configuration—The testing machine shall have both an essentially stationary head and a movable head.

Drive Mechanism—The testing machine drive mechanism shall be capable of imparting to the movable head a controlled velocity with respect to the

stationary head.

The velocity of the movable head

ASTM C297 – Load Indicator

The testing machine load-sensing device shall be capable of indicating the total force being carried by the test specimen.

This device shall be essentially free from inertia lag at the specified rate of testing and shall indicate the force with an accuracy over the force range(s) of interest

of within 61 % of the indicated value

Ultimate Tensile Strength is the most common measurement for this test and is given by the peak load. Any unique or unexpected failure of the core material

should be noted in the test results.

The sample should fail somewhere in the middle and both facings should remain adhered to the insert blocks.

ASTM C297 – Geometry

Test specimens shall have a square or circular cross-section, and shall be equal in thickness to the sandwich panel thickness.

Minimum specimen facing areas for various types of core materials are as follows:

Continuous Bonding Surfaces (for example, balsa wood, foams)—The minimum facing area of the specimen shall be 625 mm2 [1.0 in.2].

Discontinuous Cellular Bonding Surfaces (for example, honeycomb)

The required facing area of the specimen is dependent upon the cell size, to ensure a minimum number of cells are tested.

These are intended to provide approximately 60 cells minimum in the test specimen. The largest facing area listed in the table (5625 mm2 [9.0 in.2]) is a practical

maximum for this test method.

Cores with cell sizes larger than 9 mm [0.375 in.] may require a smaller number of cells to be tested in the specimen

ASTM C297 – Solution

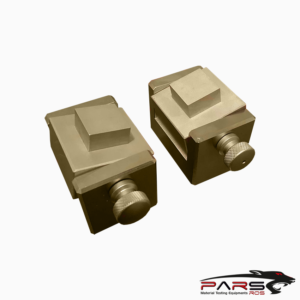

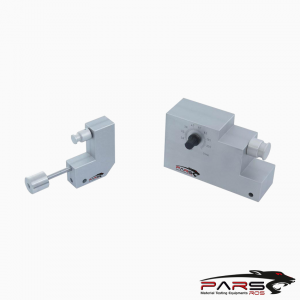

ASTM C297 – grip is specially designed for nutation, also known as articulating or swiveling.

There are two fixture options available, either with 1 degree of freedom or two degrees of freedom.

ASTM D1623 method B requires the 2 degrees of freedom fixture.

Multiple sets of square insert blocks are available to help with sample preparation and to speed up testing times.

Insert blocks are available in stock with the 1×1″ or 2×2″.

Similar Specifications

ASTM D3354 – Blocking Load of Plastic Film

ASTM D1623 – Tensile Adhesion of Foam

EN 1607 – Tensile strength of Perpendicular faces of Thermal Insulation

EN 2243 – Tensile Testing of Structural Adhesives for Aerospace

DIN 53292 – Testing of Sandwiches – Tensile Testing

Referenced Documents

ASTM Standards

C 274 Terminology of Structural Sandwich Constructions D 792 Test Methods for Density and Specific Gravity

(Relative Density) of Plastics by Displacement D 883 Terminology Relating to Plastics

D 2584 Test Method for Ignition Loss of Cured Reinforced Resins

D 2734 Test Method for Void Content of Reinforced Plas- tics

D 3039/D 3039M Test Method for Tensile Properties of Polymer Matrix Composite Materials

D 3171 Test Method for Constituent Content of Composite Materials

D 3878 Terminology for Composite Materials

D 5229/D 5229M Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix

Composite Materials

E 4 Practices for Force Verification of Testing Machines

E 6 Terminology Relating to Methods of Mechanical Test- ing

E 122 Practice for Choice of Sample Size to Estimate a Measure of Quality for a Lot or Process

E 177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E 456 Terminology Relating to Quality and Statistics

E 1309 Guide for Identification of Fiber-Reinforced Polymer-Matrix Composite Materials in Databases

E 1434 Guide for Recording Mechanical Test Data of Fiber- Reinforced Composite Materials in Databases

E 1471 Guide for Identification of Fibers, Fillers, and Core Materials in Computerized Material Property Databases

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests that

are accurate and repeatable.

The ASTM – C297 grip is specially designed for nutation, also knownas articulating or swiveling.

There are two fixture options available, either with 1 degree of freedom or two degrees of freedom.

ASTM D1623 method B requires the 2 degrees of freedom fixture.

Multiple sets of square insert blocks are available to help with sample preparation and to speed up testing times.

Insert blocks are available in stock with the 1×1″ or 2×2″.

Max. load : 20 kN

Carrier and inserts: Aluminium, anodized

Cardan adapter: Steel, nickel-plated

Temperature range: 0 … +70°C