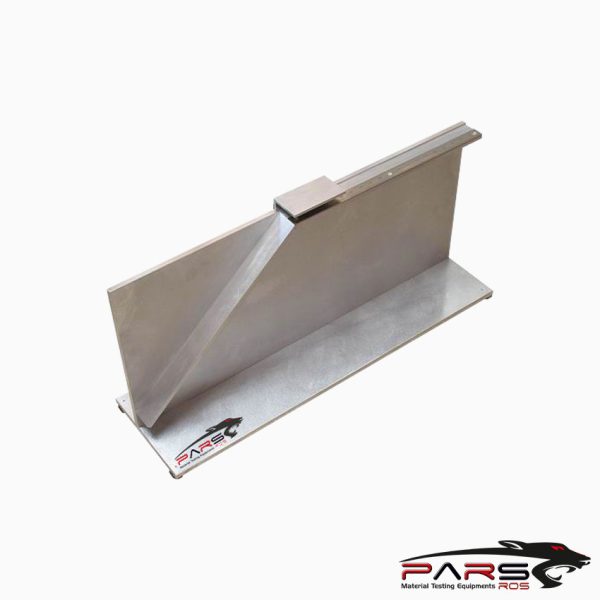

ASTM D1388 Test Fixture

ASTM D1388 covers the measurement of stiffness properties of fabrics. Bending length is measured and flexural rigidity is calculated.

Two procedures are provided.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM D1388 -Standard Test Method for Stiffness of Fabrics

ASTM D1388 covers the measurement of stiffness properties of fabrics.

Bending length is measured and flexural rigidity is calculated. Two procedures are provided.

Option A—Cantilever Test, employing the principle of cantilever bending of the fabric under its own mass.

Option B—Heart Loop Test, employing the principle of a loop formed in a fabric strip and hung vertically.

This test method ASTM D1388 applies to most fabrics including woven fabrics, air bag fabrics, blankets, napped fabrics, knitted fabrics, layered fabrics, pile fabrics.

The fabrics may be untreated, heavily sized, coated, resin-treated, or otherwise treated.

Summary of Test Method

ASTM D1388 / Option A, Cantilever Test

A specimen is slid at a specified rate in a direction parallel to its long dimension, until its leading edge projects from the edge of a horizontal surface.

The length of the overhang is measured when the tip of the specimen is depressed under its own mass to the point where the line joining the top to the edge of

the platform makes a 0.724 rad (41.5°) angle with the horizontal.

From this measured length, the bending length and flexural rigidity are calculated.

ASTM D1388 / Option B, Heart Loop Test

A strip of fabric is formed into a heart-shaped loop.

The length of the loop is measured when it is hanging vertically under its own mass. F

rom this measured length, the bending length and flexural rigidity are calculated.

ASTM D1388 / Apparatus

Option A—Cantilever Bending Tester

Horizontal Platform, with a minimum area of 38 by 200 mm (1.5 by 8 in.) and having a smooth low-friction, flat surface such as polished metal or plastic.

A leveling bubble shall be incorporated in the platform.

Indicator, inclined at an angle of 0.724 ± 0.01 rad (41.5 ± 0.5°) below the plane of the platform surface.

Movable Slide, consisting of a metal bar not less than 25 by 200 mm (1 by 8 in.) by approximately 3 mm (1⁄8 in.) thick and having a mass of

270 ± 5 g (0.6 6 0.01 lb). the overhang.

Specimen Feed Unit, motorized set to 120 mm/min (4.75 in./min) 65 %, or manual equivalent.

Cutting Die—25 ± 1 mm by 200 ± 1 mm (1 ± 0.04 in. by 8 ± 0.04 in.).

Option B—Heart Loop Tester.

Clamp and Stand, for hanging the specimen.

Scale, suitably mounted on the stand for measuring the length of the specimen loop and calibrated either in cm (in.) or directly in bending length.

NOTE : If a constant strip length is adopted, the scale may be calibrated to read directly in units of bending length.

Brass Bars, two, 25 X 3 X 75 ± 0.1 mm (1 X 3 X 0.125± 0.005 in.).

Pressure Sensitive Tape

Jig, constructed to allow positioning of the two bars with their inner edges parallel and at a distance from each other equal to the selected strip length.

*** Before conducting ASTM D1388 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Reviews (0)

Be the first to review “ASTM D1388 Test Fixture”

You must be logged in to post a review.

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Reviews

There are no reviews yet.