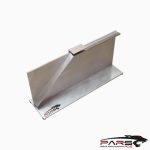

ASTM D1578 Test Fixture

ASTM D1578 covers the determination of the breaking strength of yarn in skein form.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM D1578 – Standard Test Method for Breaking Strength of Yarn in Skein Form

ASTM D1578 covers the determination of the breaking strength of yarn in skein form.

The observed breaking strength is expressed in units of force, and equations are provided to convert breaking strength to skein breaking tenacity and

to skein break factor.

NOTE 1—For the determination of the breaking strength and elongation of yarn by the single strand method, refer to Test Method ASTM D2256.

This test method ASTM D1578 is applicable to spun yarns, eithersingle or plied, composed of any fiber or blend of fibers, but is not suitable for yarns which

stretch more than 5 % when the tension is increased from 2.5 to 7.5 mN/tex or 0.03 to 0.08 gf/denier.

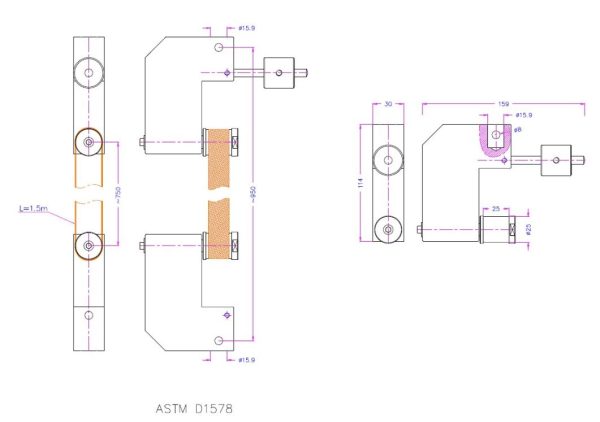

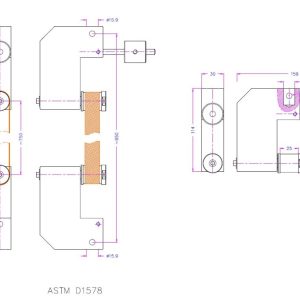

This test method provides three options based on the perimeter of the reel, the number of wraps in the skein, and the machine speed or time-to-break.

Option 1—Eighty, forty, or twenty turns on a 1.50-m or 1.5-yd reel, broken at 300 mm/min or 12 in./min.

Option 2—Fifty turns on a 1.00-m or 1-yd reel, broken at 300 mm/min or 12 in./min.

Option 3—Fifty turns on a 1-m reel, broken in 20 s.

NOTE 2—Option 1 is in general use in the United States, Option 2 is used for woolen yarns, and Option 3 has been proposed in the International Standards

Organization (ISO) for international use.

NOTE 3—Metric reels are available with 1 and 1.125-m circumferences.

Data from the two reels will be about 1 % different (see 5.6). ISO uses a 1-m circumference reel.

This test method ( ASTM D1578 ) is frequently combined with the determination of linear density carried out on the same skeins.

Special precautions for reeling such skeins are noted.

ASTM D1578 / Apparatus

Reel

A hand or motor-driven reel having a perimeter of 1.50 m or 1.5 yd for Option 1, 1.0 m or 1 yd for Option 2 , or 1 m for Option 3.

The reel shall be fitted with a traversing mechanism that will minimize bunching the yarn on the reel and with an indicator of the length wound.

A warning bell or an automatic cutoff that will operate at a specified number of turns is advisable.

It is also recommended that the reel have a collapsible arm for relaxing the tension on the skeins to facilitate their removal from the reel.

If yarn number is to be determined from the same skeins, refer to Test Method ASTM D1907 for additional reel specifications.

Package Holders

Vertical spindles for bobbins or cones if not provided as an integral part of the reel, shafts on which tubes or flanged spools can turn freely.

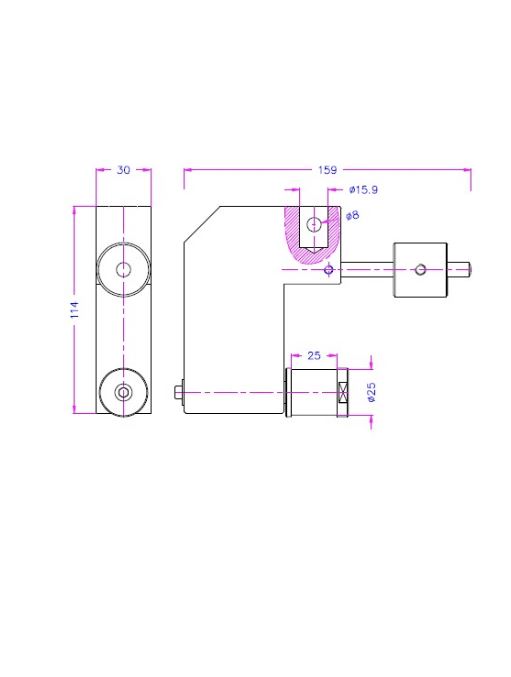

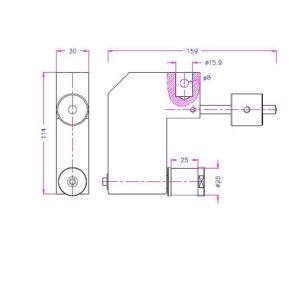

ASTM D1578 /Tensile Testing Machine

A constant-rate-of-traverse (CRT type) or constant-rate-of-extension (CRE type) tensile testing machine of suitable capacity as prescribed in

Specification ASTM D76, capable of operating the moving clamp (spool) at a uniform speed of 300 ± 10 mm/min or 12 6±0.5 in./min (for Options 1 and 2)

or capable of operating at a rate that will break the skein broken in an average time of 20 ± 3 s from the start of application of tension to the skein

(for Option 3).

The machine shall be equipped with spools not less than 25 mm or 1 in. nor more than 30 mm or 1.25 in. in both diameter and length, and supported with at least

one spool free to turn on its axis.

The distance between the spools shall be sufficient to permit placing the skeins on the spools in a wide, flat band.

Skein Holder or Rack, having parallel pegs or bars placed a sufficient distance apart to hold the skeins extended to nearly their full length without either stretching,

kinking, or entangling the yarn.

*** Before conducting ASTM D1578 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Reviews (0)

Be the first to review “ASTM D1578 Test Fixture”

You must be logged in to post a review.

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Reviews

There are no reviews yet.