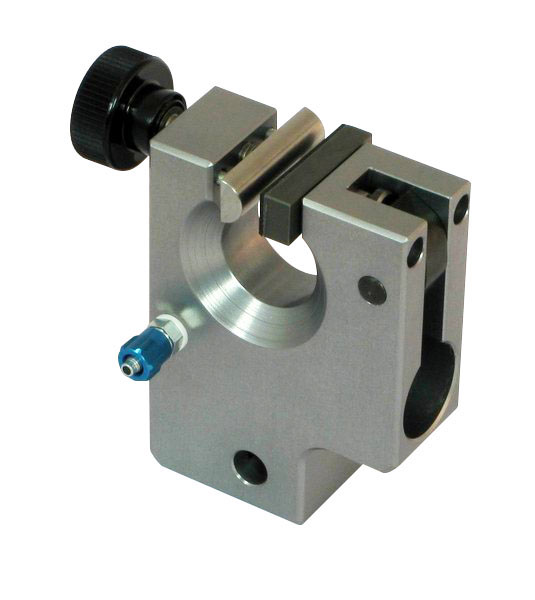

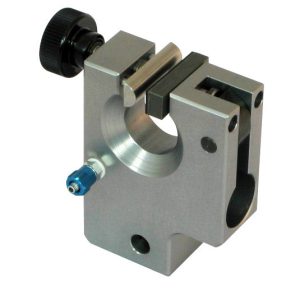

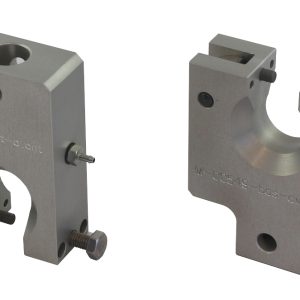

ASTM D1683 Test Fixture

ASTM D1683 measures the sewn seam strength in woven fabrics by applying a force perpendicular to the sewn seams.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM D1683 Standard Test Method for Failure in Sewn Seams of Woven Fabrics

ASTM D1683 measures the sewn seam strength in woven fabrics by applying a force perpendicular to the sewn seams.

The axis perpendicular to the sewn seam can represent either the warp yarn axis or filling yarn axis, the same axis tested when using grab Test Method

ASTM D5034.

This test method (ASTM D1683 ) is used when the seam efficiency measurement of a woven fabric sewn seam is required.

This test method is used to identify the sewn seam strength threshold at which the failure of the stitching occurs, without damage to the fabric, so that the

textile product can be repaired.

ASTM D1683 is used to identify the force at which seam strength results in slippage and displacement of warp yarns, filling yarns, or any combination

of these yarns.

ASTM D1683 / Apparatus

Tensile Testing Machine

as used in Test Method ASTM D5034 conforming to Specification ASTM D76, and preferably a constant-rate-ofextension (CRE) type of machine capable of

jaw separation

rate of 305 mm/min 6 10 mm/min [12.0 in./min 6 0.5 in./min] and an interfaced computer response to record the force-extension curve.

When a CRE type of machine is not used, a constant-rate-of traverse (CRT) type of machine may be used.

At least one clamp should be supported by a free swivel or universal joint to allow the clamp to rotate in the plane of the fabric.

*** Before conducting ASTM D1683 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Reviews (0)

Be the first to review “ASTM D1683 Test Fixture”

You must be logged in to post a review.

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Reviews

There are no reviews yet.