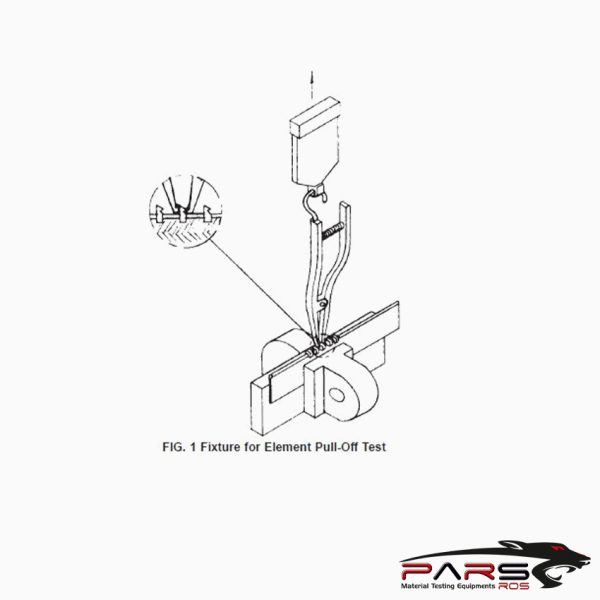

ASTM D2061 Fig.1 Test Fixture

ASTM D2061 covers the determination of the strengths for zipper and zipper parts.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM D2061- Standard Test Methods for Strength Tests for Zippers

ASTM D2061 covers the determination of the strengths for zipper and zipper parts.

STRENGTHS OF CHAINS AND ELEMENTS

These test methods cover the determination of the strengths of zipper chains and elements in tensile tests.

The element pull-off and element slippage tests apply to separate element zippers only.

ASTM D2061 / Summary of Test Method

Crosswise Strength—The ability of a zipper chain to withstand lateral stress is measured by loading to destruction a 25.4-mm (1-in.) section of a specimen in

a tensile testing machine equipped with clamps having special jaws.

Element Pull-Off—The gripping strength of a element around the bead is determined by pulling a single element from the bead at right angles to the stringer

using a tensile testing machine fitted with a specially designed fixture.

Element Slippage—The ability of a element to resist longitudinal movement along the bead of the tape is determined with a tensile testing machine fitted with

a specially designed fixture.

ASTM D2061 / Significance and Use

Crosswise Strength—This test method may be used to determine crosswise strength which measures the resistance of a zipper to such failures as tape rupture,

unmeshing, or element separation when the zipper is side stressed during use.

Element Pull-off—This test method may be used to determine element strength which measures a element’s ability to resist being fractured or pulled from the

bead of the tape when the zipper is side stressed during use.

Element Slippage—This test method may be used to determine element attachment security and measures a element’s ability to remain on the tape bead in proper

position to adjacent elements so that zipper operation can be maintained

ASTM D2061 / Apparatus

Tensile Testing Machine—ACRE type testing machine conforming to Specification D 76 with a rate-of-traverse of 305 ±10 mm (12 ± 0.5 in.)/min.

If preferred, the use of a CRT tensile testing machine is permitted.

There may be no overall correlation between the results obtained with the CRE and CRT machines.

Consequently, the two machines cannot be used interchangeably. In case of controversy, the CRE method shall prevail.

Jaws—The back jaws of the clamps on the tensile testing machine shall be at least the same width as the front jaws.

The front jaws shall be 25.4 mm (1 in.) wide and have hardened faces with horizontal grooves 1.6 mm (1⁄16 in.) apart, 0.38 mm (0.015 in.) deep, and be of a V-shape

with an included angle of 90°.

Element Pull-off Fixture, designed to grasp the head of the element by two members as shown in Fig. 1.

The fixture must be designed to fit the element under test so as to avoid element distortion.

Element Slippage Fixture, consisting of a flat plate approximately 6 mm (1⁄4 in.) wide and 2 mm (1⁄16 in.) thick which is twisted 90° midway of its length and bent

at one end through a 90° angle to give the fixture an“ L” shape.

The short leg of the “L” shall be slotted so that the two prongs thus formed will clear the bead and slip under a element in order to pull it along the bead

*** Before conducting ASTM D2061 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Reviews (0)

Be the first to review “ASTM D2061 Fig.1 Test Fixture”

You must be logged in to post a review.

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Reviews

There are no reviews yet.