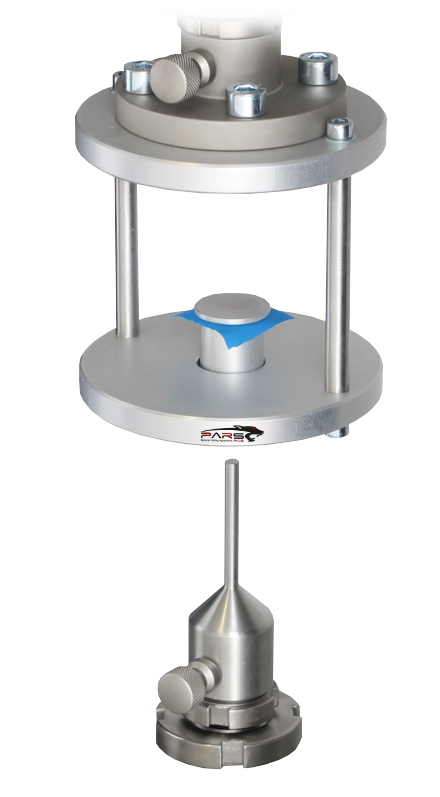

ASTM D2979 Test Fixture

ASTM D2979 covers measurement of the pressure-sensitive tack of adhesives.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

ASTM D2979 – Standard Test Method for Pressure-Sensitive Tack of Adhesives Using an Inverted Probe Machine

ASTM D2979 covers measurement of the pressure-sensitive tack of adhesives.

This test method is applicable to those adhesives which form a bond of measurable strength rapidly upon contact with another surface and which can be removed

from that surface cleanly, that is, without leaving a residue visible to the eye.

For such adhesives, tack may be measured as the force required to separate an adhesive and the adherend at the interface shortly after they have been brought into

contact under a defined load of known duration at a specified temperature.

ASTM D2979 / Significance and Use

This test method provides a quantitative measure of the pressure-sensitive tack of the adhesive.

The method is designed for the adhesive mass itself and is suitable for measuring the tack of pressure-sensitive adhesives for use on both rigid and flexible backings.

ASTM D2979 / Summary of Test Method

This test method involves bringing the tip of a cleaned probe of defined surface roughness into contact with the adhesive at a controlled rate, under a fixed pressure,

for a short time, at a given temperature; and subsequently breaking the bond formed between the probe and adhesive, also at a controlled rate.

Tack is measured as the maximum force required in breaking the adhesive bond.

ASTM D2979 / Apparatus

Probe—AType 304 stainless steel rod, 5.0 mm (0.197 in.) in diameter, machined at one end of 90° to the longitudinal axis.

The tip is finished to a surface roughness of not more than 500 or less than 250 nm (20 to 10 μin.) rms as measured by a surface-measuring device

Testing Machine—A mechanical system for bringing the adhesive into contact with the probe, automatically controlling the dwell time during which the adhesive

and probe are in contact under pressure, and subsequently pulling the adhesive away from the probe.

The machine is capable of maintaining a constant crosshead speed of 10 ± 0.1 mm/s (24 ± 0.24 in./min), sensing contact of probe with adhesive, stopping for

1 ± 0.01 s, and then reversing at the same 10 ± 0.1 mm/s (24 ± 0.24 in./min) speed.

The machine supports the probe such that its top surface is parallel to the plane of the adhesive at the time of contact to less than a 0° 10 min angle between them.

Probe to have force measurement accuracy of 61 % of reading, when calibrated in compliance with Practices ASTM E4 requirements.

*** Before conducting ASTM D2979 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Leave a Reply

You must be logged in to post a comment.