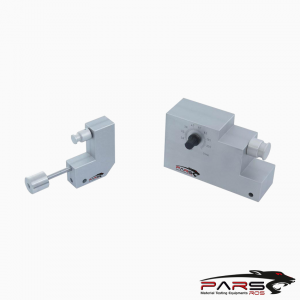

ASTM D3167- Floating Roller Peel Test Fixture

The Floating Roller Peel Test is one of the most common procedures for testing packaging tapes since it closely simulates real world applications.

ASTM D3167 is similar to the ASTM D1781 Climbing Drum Peel Test and is often used a low budget alternative when the climbing drum fixture is not available.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

ASTM D3167- Floating Roller Peel Test Fixture

The Floating Roller Peel Test is one of the most common procedures for testing packaging tapes since it closely simulates real world applications.

Types of tapes that are testing with this procedure include duct tape, masking tape, packaging tape, and certain types of transfer tapes.

ASTM D3167 is similar to the ASTM D1781 Climbing Drum Peel Test and is often used a low budget alternative when the climbing drum fixture is not available.

The floating roller peel test is often used in quality and process control testing.

Slight variations in the thickness of either the tape or the rigid backing will have an effect on the results.

*** This specific test is not as common as other tests such as 180 degree peel and the 90 degree peel test.

ASTM D3167 – Geometry

Samples are generally about 1 inch wide and can vary in thickness.

The thickness of the rigid backing should be about 2.5x as thick as the adhesive tape.

The recommended tape thickness is .63mm or about .025 inches, however other thicknesses may be used.

When the tape is .63mm thick, the rigid backing needs to be at least 1.63mm thick or about .064 inches.

ASTM D3167 – Solution

This peel test fixture must be used in conjunction with another type of tensile grip.

The tape is adhered to the back of a rigid substrate plank and the tape is pulled down through the middle of the fixture by the bottom tensile grip.

The bottom grip is most commonly a vise grip, roller grip, or some other type of self-tightening fixture.

This setup allows the tape to move rather freely which is ideal for the peel strength test.

The most common test result is the average peel strength using a data set which is usually taken out of the middle of the test.

Analysis

The most common test result is the average peel strength using a data set which is usually taken out of the middle of the test after removing the first 1/4 and last 1/4 of the data.

The maximum peel force is also an important measured metric.

Similar Specifications

ASTM D1781 – Climbing Drum Peel Fixture

*** PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Please contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations