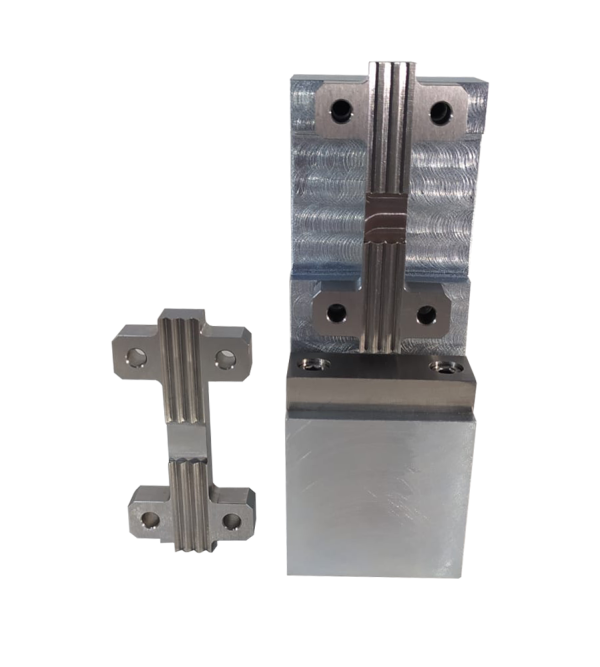

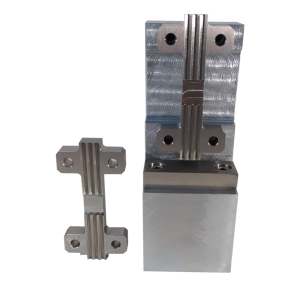

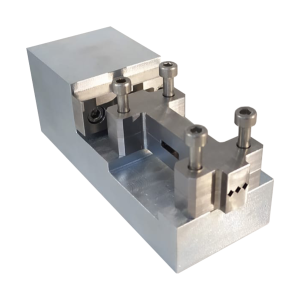

ASTM D3846 Test Fixture

ASTM D3846 covers the determination of the inplane shear strength of reinforced thermosetting plastics in flat sheet form

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

ASTM D3846 – Standard Test Method for In-Plane Shear Strength of Reinforced Plastics

ASTM D3846 covers the determination of the inplane shear strength of reinforced thermosetting plastics in flat sheet form in thicknesses ranging from

2.54 to 6.60 mm (0.100 to 0.260 in.).

Significance and Use

Shear tests of various kinds are widely used in the reinforced plastics industry to assess the strength of the reinforcement-to-resin bond in polyester-, vinyl ester-,

and epoxy-resin composites.

In addition to their importance for the generation of data for research and development, quality control, and specification purposes, such tests are of fundamental

value to the fiberous reinforcement industry, since they can be used to assess the potential of new sizing systems for the surface treatment of glass fibers.

This test method is useful for establishing the shear strength of laminates or other reinforced plastics having randomly dispersed fiber reinforcement.

While the test also lends itself to parallel-fiber reinforced plastics, it has been designed to accommodate nonparallel-fiber reinforced materials that cannot be tested

satisfactorily by the short-beam procedure described in Test Method ASTM D2344

ASTM D3846 /Summary of Test Method

In-plane shear strength, as determined by this test method, is measured by applying a compressive load to a notched specimen of uniform width.

The specimen is loaded edgewise in a supporting jig of the same description as that referenced in Test Method ASTM D695 for testing thin specimens.

Failure of the specimen occurs in shear between two centrally located notches machined halfway through its thickness and spaced a fixed distance apart

on opposing faces.

ASTM D3846 / Apparatus

Testing Machine—Any suitable testing machine capable of control of constant-rate-of-crosshead movement and comprising essentially the following:

Drive Mechanism—A drive mechanism for imparting to the movable member a uniform, controlled velocity with respect to the stationary member.

Load Indicator—A load-indicating mechanism capable of showing the total compressive load carried by the test specimen.

The mechanism shall be essentially free of inertial lag at the specified rate of testing and shall indicate the load with an accuracy of 61 % of the maximum indicated

value of the test (load).

Compression Tool—A compression tool for applying the load to the test specimen, such as Test Method ASTM D695.

*** Before conducting ASTM D3846 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Leave a Reply

You must be logged in to post a comment.