ASTM D4255 – Test Method for In-Plane Shear Properties of Polymer Matrix Composite Materials by the Rail Shear Method

ASTM D4255 – A Testing Fixture

ASTM D4255 – This test method indicates the cutting properties in the plane of a high modulus fiber-reinforced composite materials by two procedures.

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- teknik özellikler

Açıklama

Açıklama

ASTM D4255 – Test Method for In-Plane Shear Properties of Polymer Matrix Composite Materials by the Rail Shear Method

ASTM D4255 – A Testing Fixture

ASTM D4255 – This test method indicates the cutting properties in the plane of a high modulus fiber-reinforced composite materials by two procedures.

As regards the procedure A, laminates stuck between two pairs of loading rails are tested.

When the tension load is applied to the rails, shear forces arise in the specimen.

In procedure B, laminates clamped on opposite edges with a tensile or compressive load applied to a third pair of rails in the center are tested.

The application of this method is for continuous-fiber or discontinuous-fiber-reinforced polymer matrix composites in the following material forms:

Laminates wich are composed only of woven fabric filamentary laminae with the warp direction oriented parallel or perpendicular to the mounting rails.

Laminates wich are composed only of unidirectional fibrous laminae, with the fiber direction oriented parallel or perpendicular to the mounting rails.

Laminates of balanced and symmetric construction, with the 0° direction oriented parallel or perpendicular to the mounting rails.

Short-fiber-reinforced composites with a majority of the fibers being randomly distributed

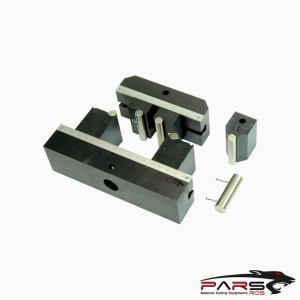

Rail Shear Fixtures

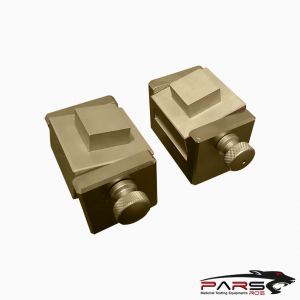

Two-Rail Shear—The test fixture consists of two pairs of rails which can clamp the test specimen with through bolts.

The rails are then attached to the test machine through pins, a load plate that also aligns the rails with each other, and a clevis hat connects directly to the

test machine.

This equipment is typical but not the only configuration usable. The two-rail shear fixture can be compression loaded.

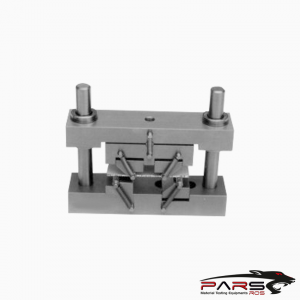

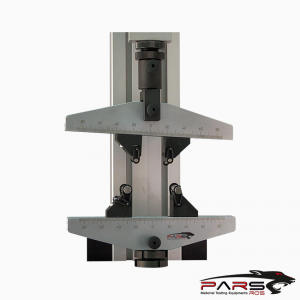

Three-Rail Shear. The test fixture consists of three pairs of rails that clamp the test specimen with through bolts.

The two outside pairs of rails are attached to a base plate that rests on the test machine.

The third (middle) pair of rails are guided through a slot in the top of the base fixture.

The middle rails can be tensile loaded, which requires fastening the base fixture to the test machine.

This equipment is typical but not the only configuration that is usable.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

teknik özellikler

Teknik Detaylar İçin Lütfen Bizimle İletişime Geçiniz

Please contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

| Test Standard | ASTM D 4255A / no ISO equivalent |

| Maximum Load | 75 kN |

| Temperature Range | from -80 °C to 149 °C |

| Specimen Thickness | 1.3-3.2 mm |

| Specimen Width | 74-76 mm |

| Specimen Length | 141-159 mm |

| Mass | 11.30 kg |