ASTM D543 Test Fikstürü

ASTM D543 cover the evaluation of all plastic materials including cast, hot-molded, cold-molded, laminated resinous products, and sheet materials for

resistance to chemical reagents.

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- Değerlendirmeler (0)

- TEKNİK ÖZELLİKLER

Açıklama

ASTM D543- Standard Practices for Evaluating the Resistance of Plastics to Chemical Reagents

ASTM D543 cover the evaluation of all plastic materials including cast, hot-molded, cold-molded, laminated resinous products, and sheet materials for

resistance to chemical reagents.

Three procedures are presented, two under practice A (Immersion Test), and one under practice B (Mechanical Stress and Reagent Exposure under

Standardized Conditions of Applied Strain).

These practices include provisions for reporting changes in weight, dimensions, appearance, color, strength, and other mechanical properties.

Standard reagents are specified to establish results on a comparable basis without precluding the use of other chemical reagents pertinent to specific chemica

l resistance requirements.

Provisions are made for various exposure times, stress conditions, and exposure to reagents at elevated temperatures.

The type of conditioning (immersion or wet patch/wipe method) depends upon the end-use of the material.

If the material is used as a container or transfer line, immersion of the specimens is used.

If the material will only see short exposures or will be used in proximity and reagent will splash or spill on the material, the wet patch or wipe method of

applying reagent to the material is used.

The effect of chemical reagents on properties shall be determined by making measurements on standard specimens for such tests before and after immersion

or stress, or both, if so tested.

ASTM D543 / APPARATUS

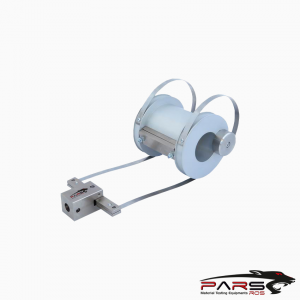

Containers

Suitable containers for submerging specimens in chemical reagents.

They must be resistant to the corrosive effects of the reagents being used.

Provide venting when using volatile reagents at elevated temperatures.

Tightly sealed containers are preferred for room temperature testing to minimize loss.

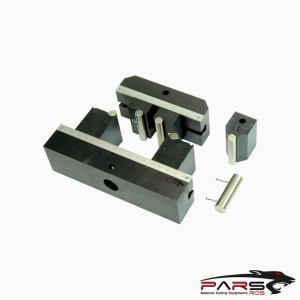

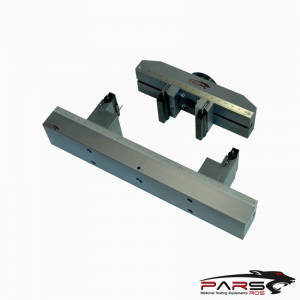

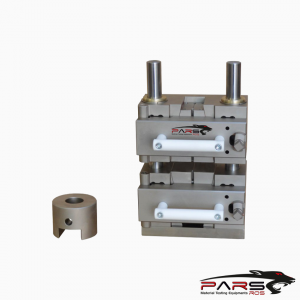

ASTM D543 / Strain Jigs

Jigs are to be capable of supplying known amounts of strain to test specimens.

These jigs are three point flexural strain devices capable of affixing the test specimen to the fixtures in such a way that intimate contact is maintained

between the test specimen and the fixture along the entire length of the gage area or specimen area to be tested.

The clamping system should allow for thermal expansion of the material when exposure to elevated temperature is specified.

ASTM D543 / NOTE

The jigs should be constructed such that they are able to maintain a constant level of strain under the conditions of testing.

Significant distortion or changes in dimension of the jig during the chemical exposure testing will result in strain changes and should be avoided.

Regarding the material of construction for the jigs, one should recognize that dissolution of metal ions may alter the ESCR behavior of certain polymers.

For example, transition metal oxides can cause autocatylic oxidation in polyethylene, which would in turn likely influence the ESCR behavior of the polymer material.

If some constituent of a metal jig preferentially corrodes without causing apparent distortion or an apparent change in jig shape (for example, dezincification

corrosion of yellow brass, decarburization of carbon steel, or preferential etching of carbides), this may affect ESCR results due to the electrochemical effects of

dissolved metal ions and/or metal oxide formation.

Thus it is critical to monitor any effects on the jigs themselves.

*** Before conducting ASTM D543 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Bir yanıt yazın

Yorum yapabilmek için oturum açmalısınız.