ASTM D5448 Test Fixture

ASTM D5448 determines the inplane shear properties of wound polymer matrix composites reinforced by highmodulus continuous fibers.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM D5448 – Standard Test Method for Inplane Shear Properties of Hoop Wound Polymer Matrix Composite Cylinders

ASTM D5448 determines the inplane shear properties of wound polymer matrix composites reinforced by highmodulus continuous fibers.

It describes testing of hoop wound (90°) cylinders in torsion for determination of inplane shear properties.

ASTM D5448 / Significance and Use

This test method is designed to produce inplane shear property data for material specifications, research and development, quality assurance, and structural design

and analysis.

Factors that influence the inplane shear response and should therefore be reported are material, method of material preparation, specimen preparation, specimen

conditioning, environment of testing, specimen alignment and gripping, speed of testing, void content, and fiber volume fraction.

Properties, in the test direction, that may be obtained from this test method are as follows:

Inplane Shear Strength

Inplane Shear Strain at Failure

Inplane Shear Modulus

ASTM D5448 / Apparatus

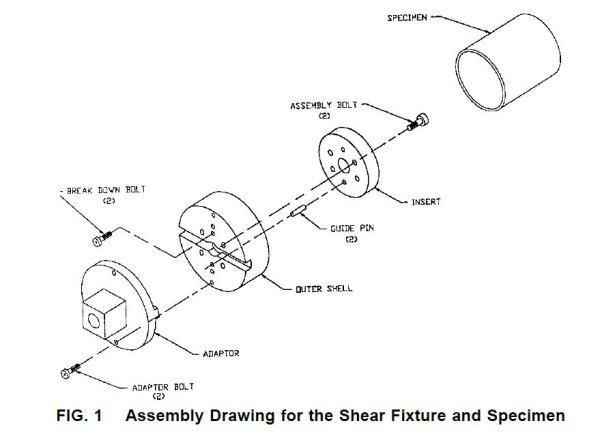

Inplane Shear Fixture—The inplane shear fixture consists of a steel outer shell, insert, and adaptor.

An assembly drawing for these components and the test fixture is shown in Fig. 1.

Outer Shell—The outer shell is circular with a concentric circular hollow in one face, a groove along the diameter of the other face, and a center hole

through the thickness.

Along the diameter perpendicular to the groove, three pairs of small eccentric holes are placed at three radial distances.

The two outer pairs of holes are threaded.

Four additional threaded holes are placed at the same radial distance as the innermost pair of holes at 90° intervals starting 45° from the diameter that

passes through the center groove.

Insert—The fixture insert is circular with a center hole through the thickness .

Two sets of holes are placed along a concentric centerline.

These holes align with the innermost set of holes in the outer shell.

The set of 4 holes at 90° intervals are counterbored.

The insert is fastened inside the hollow of the outer shell to form the concentric groove used to put the specimen in the fixture.

Adaptor—The adaptor is circular with a square central torque nut raising out of one face, a flange along a diameter on the other face, and a central hole.

Two bolt holes are placed equidistant from the adaptor center on a diameter perpendicular to the centerline of the flange.

The adaptor is fastened to the outer shell. The flange of the adaptor fits into the groove of the outer shell.

ASTM D5448 / Testing Machine, comprised of the following:

Fixed Member—A fixed or essentially stationary member, with respect to rotation, to which one end of the torsion specimen/fixture/adaptor assembly

Rotational Member—A rotational member to which the opposite end of the torsion specimen/fixture/adaptor assembly, can be attached.

Either the rotational member or the fixed member shall be free to move axially to prevent the application of axial forces or the axial load shall be limited to

5 % of the axial strength of the material.

Drive Mechanism, for imparting to the movable member a uniform controlled angular velocity with respect to the fixed member.

*** Before conducting ASTM D5448 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Reviews (0)

Be the first to review “ASTM D5448 Test Fixture”

You must be logged in to post a review.

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Reviews

There are no reviews yet.