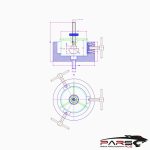

ASTM D5751 Test Fixture

ASTM D5751 covers performance levels for adhesives to be used in laminate joints in nonstructural lumber products.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM D5751 – Standard Specification for Adhesives Used for Laminate Joints in Nonstructural Lumber Products

ASTM D5751 covers performance levels for adhesives to be used in laminate joints in nonstructural lumber products.

Such products include, but are not limited to, interior and exterior mouldings, window and door components or parts, and bonded lumber panels.

This specification is to be used to evaluate adhesives as well as the adhesive bonds in nonstructural-glued-lumber products.

ASTM D5751 / Significance and Use

Adhesives are classified as dry use or wet use.

Each classification includes consideration of short-term in-transit exposure conditions at temperatures up to 220°F.

These test methods are designed to determine the performance level of a nonstructural wood adhesive when used in a laminate joint for a depiction of a

laminate joint.

The dry test and exposure conditions and treatments are to evaluate adhesives and adhesive bonds of laminate joints in nonstructural bonded lumber products for

typical service conditions.

The 220°F test, a more severe test, is designed to evaluate the product after exposure to short-term elevated temperature.

This test method is intended to simulate conditions that might be experienced in transit, further processing, or in service bonds in a laminate joint that is the

industrial-end product of a manufacturing process.

The use of the specification for this purpose requires close evaluation of the configuration of the joint, the wood used, and the manufacturing process.

Special circumstances may require modification of some of the details of these procedures.

Record these variations in the report sections, as they may have an impact on the results obtained.

As the industrially manufactured laminate joint product is often handled, machined, and shipped within a few hours of manufacture, it may not have reached the

maximum performance level before it is shipped or tested.

To avoid potential product damage, the adhesive-performance level should be determined by the laminate-joint manufacturer prior to initial handling and early

shipment.

Before beginning the full testing process, the testing laboratory should ensure that the product conforms with the performance level certified by the adhesive

manufacturer and has not been damaged by early handling and shipping.

ASTM D5751 / Apparatus

Testing Machine—Capacity of not less than 15 000 lb (6810 kg) in compression, fitted with a shearing tool containing a self-aligning seat to ensure uniform lateral

distribution of the load, capable of maintaining a uniform rate of loading in accordance with 10.1, and located in an atmosphere such that the moisture content of

the specimens to be tested dry is not significantly altered during testing.

*** Before conducting ASTM D5751 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Reviews (0)

Be the first to review “ASTM D5751 Test Fixture”

You must be logged in to post a review.

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Reviews

There are no reviews yet.