ASTM D6364 Test Fikstürü

ASTM D6364 covers the procedures for evaluation of the deformations of a geosynthetic or combination of geosynthetics (that is, geocomposite

(excluding geotextiles, geomembranes, and geosynthetic clay liners)) under short-term compressive loading.

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- Değerlendirmeler (0)

- TEKNİK ÖZELLİKLER

Açıklama

ASTM D6364 – Standard Test Method for Determining Short-Term Compression Behavior of Geosynthetics

ASTM D6364 covers the procedures for evaluation of the deformations of a geosynthetic or combination of geosynthetics (that is, geocomposite

(excluding geotextiles, geomembranes, and geosynthetic clay liners)) under short-term compressive loading.

This test method is strictly an index test method to be used to verify the compressive strength consistency of a given manufactured geosynthetic(s).

Results from this test method should not be considered as an indication of actual or long-term performance of the geosynthetic(s) in field applications.

ASTM D6364 / Significance and Use

The compression behavior test for geosynthetics is intended to be an index test.

It is anticipated that the results of the compression behavior test will be used to evaluate product.

The results of the analyses may also be used to compare the relative compressive yield points of materials that exhibit a detectable compressive yield point.

It is anticipated that this test will be used for quality control testing to evaluate uniformity and consistency within a lot or between lots where sample geometry

factors (for example, thickness) or materials may have changed.

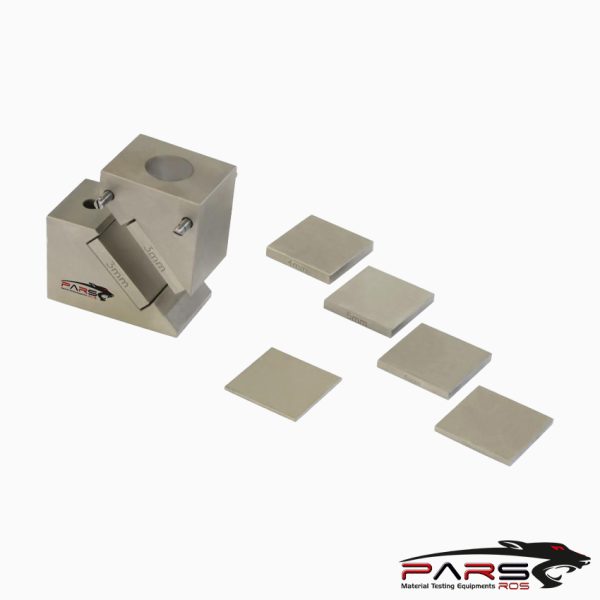

ASTM D6364 / Apparatus

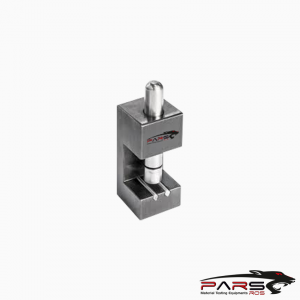

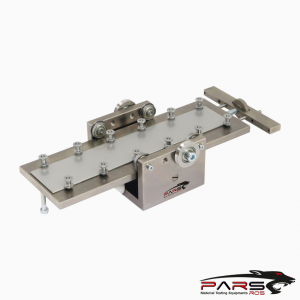

ASTM D6364 / Loading Mechanism—The loading mechanism shall be capable of applying compressive loads at a constant rate of deformation of 10 % on the

nominal thickness of the test specimen per minute or 1 mm/min, whichever is greater.

The capacity of the load frame shall be at least two times greater than the compressive yield point of or the maximum load applied to the specimen

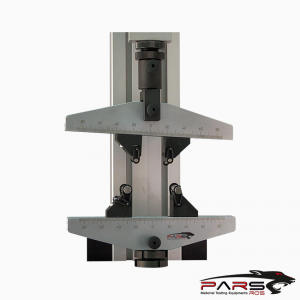

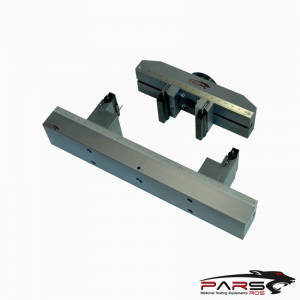

Fixed Plate—The fixed plate shall be larger than the specimen to be tested.

It shall also be flat, smooth, and completely and uniformly supported.

Movable Plate—The movable plate shall be of sufficient thickness and strength to preclude any bending during loading.

It shall be parallel to the fixed plate and attached to the compression mechanism.

A spherical loading block of the suspended, self-aligning type is recommended.

The dimensions and shape of the movable plate shall depend on the specimen dimensions and geometry.

In general, both length and width of the movable plate should each be at least 20 % greater than the length and width of the specimens.

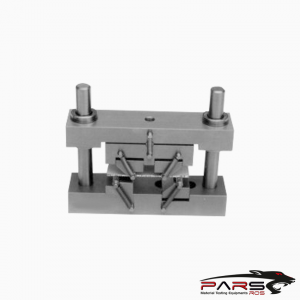

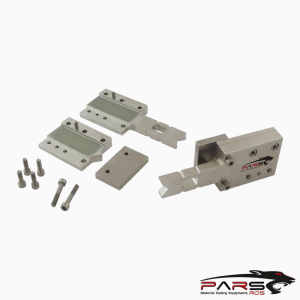

Variable Plates (Required for High-Flow Products per Specification ASTM D7001)—Variable inclined plates or set angled blocks should be used to test

the specimen under non-axial conditions.

The test apparatus shall have one fixed plate and one movable plate set angled blocks with a movable base block with a roller system to allow lateral movement of

the block during deformation .

The base and top inclined plates can be adjustable angle plates.

The base and top inclined plates or blocks must have a matched set of angles that differ by no more than 0.5°.

The inclined plates or blocks shall be roughened or ribbed to keep specimen from sliding down the fixed plate or block during the test.

The samples should be marked in regards to plates or blocks to check for slippage during the test.

Allowable percent reduction in strength based on the load angle should also be agreed upon.

*** Before conducting ASTM D6364 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Bir yanıt yazın

Yorum yapabilmek için oturum açmalısınız.