ASTM D6484 – Standard Test Method for Open-Hole Compressive Strength of Polymer Matrix Composite Laminates

ASTM D6484 – This test method determines the open-hole compressive strength of multidirectional polymer matrix composite laminates reinforced

by high-modulus fibers.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM D6484 – Standard Test Method for Open-Hole Compressive Strength of Polymer Matrix Composite Laminates

ASTM D6484 – This test method determines the open-hole compressive strength of multidirectional polymer matrix composite laminates reinforced

by high-modulus fibers.

The composite material forms are limited to continuous-fiber or discontinuous-fiber (tape or fabric, or both) reinforced composites in which the laminate is

balanced and symmetric with respect to the test direction.

The open hole is used as a weak spot in the sample which causes the rupture to occur near it.

The shear fixtures tend to be used either with compression platens or with fatigue rated wedge grips.

ASTM D6484 – Significance and Use

This test method is designed to produce notched compressive strength data for structural design allowables, material specifications, research and development,

and quality assurance.

Factors that influence the notched compressive strength and shall therefore be reported include the following:

Material, methods of material fabrication, accuracy of lay-up, laminate stacking sequence and overall thickness, specimen geometry, specimen preparation

(especially of the hole),

specimen conditioning, environment of testing, specimen alignment and gripping, loading procedure, speed of testing, void content, and volume percent

reinforcement.

Properties that may be derived from this test method include open-hole (notched) compressive strength (OHC).

ASTM D6484 – Geometry

The sample is a long bar, about a foot in length. A hole is drilled in the center to create an area of weakness that is the focus for the test.

ASTM D6484 – Solution

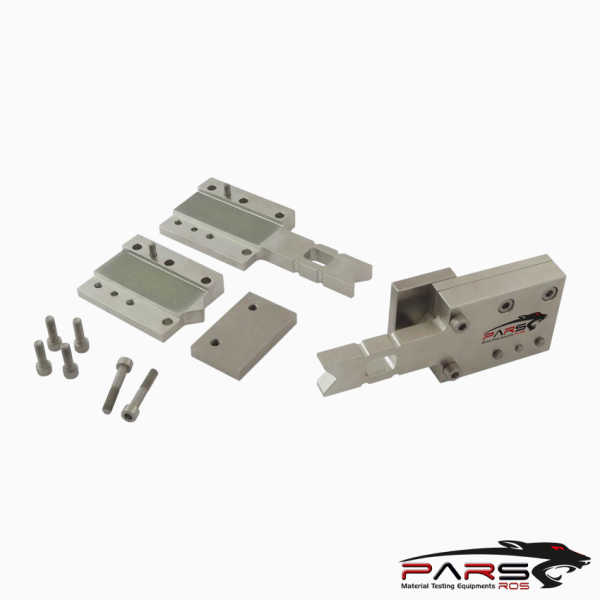

This procedures calls for a open hole compression shear fixture. The fixture is end loaded, and both sides exert a compressive force onto the sample.

Referenced Documents

ASTM Standards

ASTM D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

ASTM D883 Terminology Relating to Plastics

ASTM D2584 Test Method for Ignition Loss of Cured Reinforced Resins

ASTM D2734 Test Methods for Void Content of Reinforced Plastics

ASTM D3039/D3039M Test Method for Tensile Properties of Polymer Matrix Composite Materials

ASTM D3171 Test Methods for Constituent Content of Composite Materials

ASTM D3878 Terminology for Composite Materials

ASTM D5229/D5229M Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite Materials

ASTM D5687/D5687M Guide for Preparation of Flat Composite Panels with Processin Guidelines for Specimen Preparation

ASTM E4 Practices for Force Verification of Testing Machines

ASTM E6 Terminology Relating to Methods of Mechanical Testing

ASTM E83 Practice for Verification and Classification of Extensometer Systems

ASTM E122 Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or Process

ASTM E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

ASTM E456 Terminology Relating to Quality and Statistics

ASTM E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

ASTM E1309 Guide for Identification of Fiber-Reinforced Polymer-Matrix Composite Materials in Databases

ASTM E1434 Guide for Recording Mechanical Test Data of Fiber-Reinforced Composite Materials in Databases

ASTM E1471 Guide for Identification of Fibers, Fillers, and Core Materials in Computerized Material Property Databases

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

TECHNICAL SPECIFICATIONS

Please contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations