ASTM D6873 Test Fixture

ASTM D6873 provides instructions for modifying static bearing test methods to determine the fatigue behavior of composite materials subjected to cyclic bearing forces.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

ASTM D6873 – Standard Practice for Bearing Fatigue Response of Polymer Matrix Composite Laminates

ASTM D6873 provides instructions for modifying static bearing test methods to determine the fatigue behavior of composite materials subjected to cyclic bearing

forces.

The composite material forms are limited to continuous-fiber reinforced polymer matrix composites in which the laminate is both symmetric and balanced with

respect to the test direction.

This practice supplements Test Method ASTM D5961/D5961M with provisions for testing specimens under cyclic loading.

Several important test specimen parameters (for example, fastener selection, fastener installation method, and fatigue force/stress ratio) are not mandated by this

practice; however, repeatable results require that these parameters be specified and reported.

This practice is limited to test specimens subjected to constant amplitude uniaxial loading, where the machine is controlled so that the test specimen is subjected to

repetitive constant amplitude force (stress) cycles.

Either engineering stress or applied force may be used as a constant amplitude fatigue variable.

The repetitive loadings may be tensile, compressive, or reversed, depending upon the test specimen and procedure utilized

ASTM D6873 / Significance and Use

This practice provides supplemental instructions for using Test Method ASTM D5961/D5961M to obtain bearing fatigue data for material specifications,

research and development, material design allowables, and quality assurance.

The primary property that results is the fatigue life of the test specimen under a specific loading and environmental condition.

Replicate tests may be used to obtain a distribution of fatigue life for specific material types, laminate stacking sequences, environments, and loading conditions.

Guidance in statistical analysis of fatigue data, such as determination of linearized stress life (S-N) curves, can be found in Practice ASTM E739.

This practice can be utilized in the study of fatigue damage in a polymer matrix composite bearing specimen.

The loss in strength associated with fatigue damage may be determined by discontinuing cyclic loading to obtain the static strength using Test Method

ASTM D5961/D5961M.

ASTM D6873 / Apparatus

ASTM D6873 / Testing Machine—In addition to the requirements described in Test Method ASTM D5961/D5961M, the testing machine shall be in conformance

with Practice

ASTM E467 and shall satisfy the following requirements:

ASTM D6873 / Drive Mechanism and Controller—The velocity of the movable head shall be capable of being regulated under cyclic force (stress) conditions.

The drive mechanism and controller shall be capable of imparting a continuous sinusoidal loading wave form to the specimen.

It is important to minimize drift of the fatigue loading away from the maximum and minimum values.

Achieving such accuracy is critical in the development of reliable fatigue life data since small errors in loading may result in significant errors in fatigue life.

It is recommended that the test controller be equipped with a Test Amplitude controller, capable of monitoring the fatigue forces at least once every three cycles.

ASTM D6873 / Force Indicator—The force indicator shall be in compliance with Practices ASTM E4.

The fatigue rating of the force indicator shall exceed the forces at which testing will take place.

Additionally, this practice recommends compliance with Practice ASTM E467 for the development of a system dynamic conversion for the verification of specimen

forces to within 1 % of true forces.

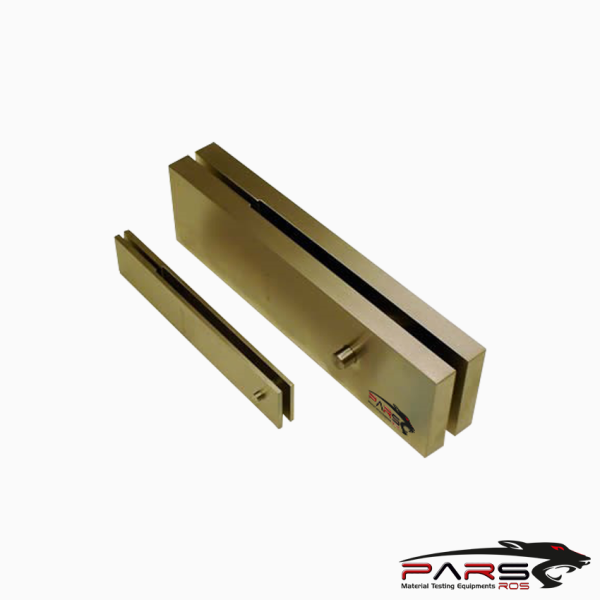

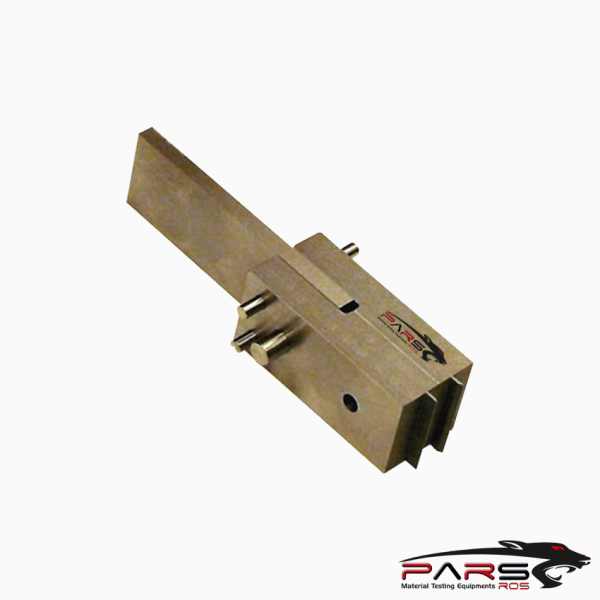

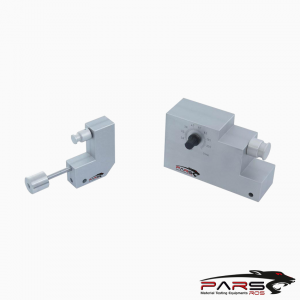

ASTM D6873 / Grips—The grips shall have sufficient fatigue rating for forces at which testing will take place.

ASTM D6873 / Support Fixture—If compressive forces are applied, either during fatigue loading or during quasi-static loading to determine hole elongation,

a support fixture shall be used to stabilize the specimen.

The support fixture shall be in accordance with that described in Test Method ASTM D5961/D5961M Procedure B for single shear specimens, and with that

described in Test Method ASTM D5961/D5961M Procedure D for double shear specimens.

*** Before conducting ASTM D6873 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Leave a Reply

You must be logged in to post a comment.