ASTM D7078 – Standard Test Method for Shear Properties of Composite Materials by V-Notched Rail Shear Method

ASTM D7078 V-notched Rail Shear Fixture

ASTM D7078 – This test method covers the determination of the shear properties of high-modulus fiber-reinforced composite materials by clamping the ends of a

V-notched specimen between two pairs of loading rails. When loaded in tension, the rails introduce shear forces into the specimen through the specimen faces.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM D7078 – Standard Test Method for Shear Properties of Composite Materials by V-Notched Rail Shear Method

ASTM D7078 – V-notched Rail Shear Fixture

ASTM D7078 – This test method covers the determination of the shear properties of high-modulus fiber-reinforced composite materials by clamping the ends of a

V-notched specimen between two pairs of loading rails. When loaded in tension, the rails introduce shear forces into the specimen through the specimen faces.

In comparison, the specimen of Test Method D5379/D5379M is loaded through its top and bottom edges.

Face loading allows higher shear forces to be applied to the specimen, if required.

Additionally, the present test method utilizes a specimen with a larger gage section than the V-notched specimen of Test Method D5379/D5379M.

In both test methods, the use of a V-notched specimen increases the gage section shear stresses in relation to the shear stresses in the vicinity of the grips,

thus localizing the failure within the gage section while causing the shear stress distribution to be more uniform than in a specimen without notches.

In comparison, Test Method D4255/D4255M utilizes an unnotched specimen clamped between two pairs of loading rails that are loaded in tension.

Also, in contrast to Test Method D4255/D4255M, the present test method provides specimen gripping without the need for holes in the specimen.

The composite materials are limited to continuous-fiber or discontinuous-fiber-reinforced composites in the following material forms:

*Laminates composed only of unidirectional fibrous laminae, with the fiber direction oriented either parallel or perpendicular to the fixture rails.

* Laminates of balanced and symmetric construction, with the 0° direction oriented either parallel or perpendicular to the fixture rails.

*Laminates composed of woven, braided, or knitted fabric filamentary laminae.

* Short-fiber-reinforced composites with a majority of the fibers being randomly distributed.

Significance and Use

This shear test is designed to produce shear property data for material specifications, research and development, quality assurance, and structural design

and analysis.

Either in-plane or interlaminar shear properties may be evaluated, depending upon the orientation of the material coordinate system relative to the loading axis.

Factors that influence the shear response and should therefore be reported include:

Material, methods of material preparation and lay-up, specimen stacking sequence, specimen preparation, specimen conditioning, environment of testing,

specimen alignment and gripping, speed of testing, time at temperature, void content, and volume percent reinforcement.

* In anisotropic materials, properties may be obtained in any of the six possible shear planes by orienting the testing plane of the specimen with the desired

material plane (1-2 or 2-1, 1-3 or 3-1, 2-3 or 3-2). Only a single shear plane may be evaluated for any given specimen.

Properties, in the test direction, which may be obtained from this test method, include the following:

** Shear stress versus engineering shear strain response,

** Ultimate shear strength,

** Ultimate engineering shear strain, and

**Shear chord modulus of elasticity.

ASTM D7078 – Geometry

The sample is similar to the one from the Iosipescu test, however it is slightly more square. The V-notch is made at 90 degrees in the center of both the top

and bottom of the sample.

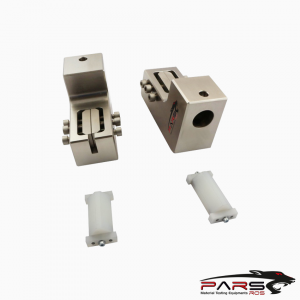

Solution

This test requires a Rail Shearing Fixture which is specifc to ASTM D7078. Along with the metal fixtures, plastic centering triangles are also used to align the sample.

Different sized rail shear fixtures are available, including those with an increased amount of tightening screws for higher loads.

ASTM D7078 – Testing Fixtures

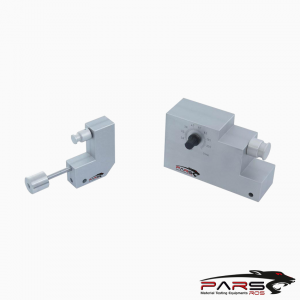

Shear Test Fixtures are designed for in-plane or interlaminar shear testing of composite materials.

The V-Notched Beam Method, or more commonly known as the Iosipescu Shear Method, was standardized into ASTM D5379 in 1993,

while the V-Notched Rail Shear Method was more recently introduced in 2005 under ASTM D7078.

Both test methods share many common characteristics and have the distinctive V-notches in the specimen design, which serve to create a localized and

approximate uniform shear stress zone between the notches. Also, a ±45° two-element strain gauge is often used to directly verify the shear strains applied.

*** It’s important to note that the two fixtures in ASTM D7078 and D5379 are quite different in their specimen design, the way in which

load is applied to the specimen, and consequently, the type of results obtained.

To ensure alignment of the specimen to the load line, for the ASTM D7078 V-Notched Rail Shear Fixture, plastic V-bars are included.

These are placed between the two half fixtures to align the specimen as the clamping screws are tightened.

Once setup, the location devices can be removed and testing can begin.

The clamping screws on each fixture half are provided on both front and back so that the clamping jaws can be properly centered depending on the specimen

thickness.

Also, with a thick lock ring, both upper and lower fixture halves are rigidly held, ensuring an accurate test.

Analysis

Maximum shear stress is the most common measure of shear strength and it is divided by the total cross-sectional shear zone.

The strain is concentrated in the center of the sample and can be more accurately measured with a strain gauge or laser extensometer.

Similar Specifications

ASTM D5379 – Iosipescu Shear Test

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

TECHNICAL SPECIFICATIONS

Please contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations