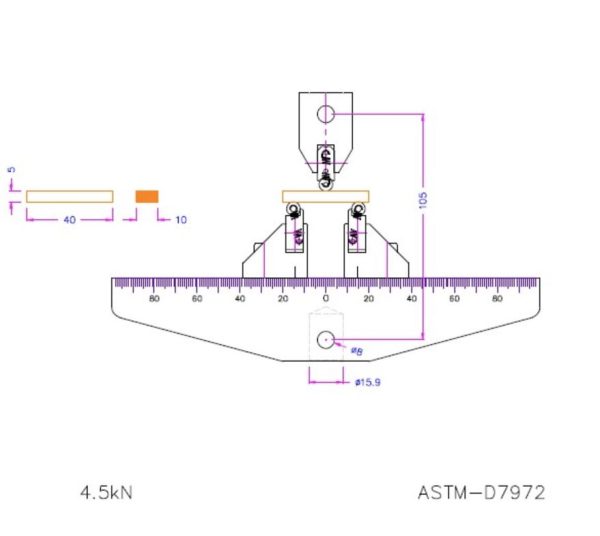

ASTM D7972 Test Fixture

ASTM D7972 covers determination of the flexural strength of manufactured carbon and graphite articles using a square, rectangular or cylindrical beam

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM D7972- Standard Test Method for Flexural Strength of Manufactured Carbon and Graphite Articles Using Three-Point Loading at Room Temperature

ASTM D7972 covers determination of the flexural strength of manufactured carbon and graphite articles using a square, rectangular or cylindrical beam

in three-point loading at room temperature

ASTM D7972 / Siginifance and Use

This test method provides a framework for material development, quality control, characterization, and design data generation purposes.

The user needs to assess the applicability of the method on the specific material and for the intended use, as shown by the interlaboratory study.

This test method determines the maximum loading on a graphite specimen with simple beam geometry in three–point bending, and it provides a means for

the calculation of flexural strength at ambient temperature and environmental conditions.

The flexure stress is computed based on simple beam theory with assumptions that the material is isotropic and homogeneous, the moduli of elasticity in tension

and compression are identical, and the material is linearly elastic.

For materials with large grains, the minimum specimen dimension should be significantly larger than the maximum grain size

Flexural strength of a group of test specimens is influenced by several parameters associated with the test procedure.

Such factors include the loading rate, test environment, specimen size, specimen preparation, and test fixtures.

Specimen sizes and fixtures should be chosen to reduce errors due to material variability or testing parameters, such as friction and non-parallelism of specimen

surfaces.

The flexural strength of a manufactured graphite or carbon material is dependent on both its inherent resistance to fracture and the size and severity of flaws.

Variations in these cause a natural scatter in test results for a sample of test specimens.

Fractographic analysis of fracture surfaces, although beyond the scope of this standard, is highly recommended for all purposes

The three-point test configuration exposes only a very small portion of the specimen to the maximum stress.

Therefore, three-point flexural strengths are likely to be much greater than four-point flexural strengths.

Three-point flexure has some advantages. It uses simpler test fixtures, allowing small specimen testing and fracture toughness measurements.

However, four-point flexure is preferred and recommended for most characterization purposes.

ASTM D7972 / Apparatus

ASTM D7972 / Loading—Specimens may be loaded in any suitable testing machine provided that uniform rates of loading can be maintained.

The testing machine shall be equipped with a means for retaining read-out of the maximum force applied to the specimen.

The accuracy of the testing machine shall be in accordance with Practice E4.

Fixture—The three-point loading fixture shall consist of bearing blocks or cylindrical bearings spaced in a three-point loading configuration

(see Test Method ASTM C1161).

A hardened steel bearing block or its equivalent is necessary to prevent distortion of the loading member.

The fixture shall ensure that forces applied to the beam are normal only and without eccentricity through the use of spherical bearing blocks

(see Test Method ASTM C78) or articulating roller bearing assemblies (see Test Method ASTM C1161).

The cylindrical bearing length shall be such that the test specimen width is fully supported, and the cylindrical bearing diameter shall be 0.75 to 1.5 times

the specimen thickness/diameter.

The lower support bearings shall be free to rotate in order to relieve frictional constraints.

The middle load bearing of the three-point fixture need not rotate.

The three bearings shall be parallel over their length.

The load application bearing (upper bearing) shall be centered with respect to the two lower support bearings within 60.10 mm.

The directions of loads and reactions may be maintained parallel by judicious use of linkages, rocker bearings, and flexure plates.

Eccentricity of loading can be avoided by the use of spherical bearing blocks or articulating roller bearings.

ASTM D7972 / Semi-articulated Three-point Fixture—Specimens prepared in accordance with the parallelism requirements of 6.1 may be tested in a

semi-articulated fixture.

The middle bearing shall be fixed and not free to roll.

The two outer bearings shall be parallel to each other over their length.

The two outer bearings shall articulate together as a pair to match the specimen surface, or the middle bearing shall articulate to match the specimen surface.

All three bearings shall rest uniformly and evenly across the specimen surface.

The fixture shall be designed to apply equal load to the two outer bearings.

ASTM D7972 / Fully-articulated Three-point Fixture—Specimens that do not meet the parallelism requirements of 6.1 shall be tested in a fully-articulated fixture.

Well-machined specimens may also be tested in a fully-articulating fixture.

The two support (outer) bearings shall be free to roll outwards.

The middle bearing shall not roll.

Any two of the bearings shall becapable of articulating to match the specimen surface.

All threebearings shall rest uniformly and evenly across the specimen surface.

The fixture shall be designed to apply equal load to the two outer bearings.

*** Before conducting ASTM D7972 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

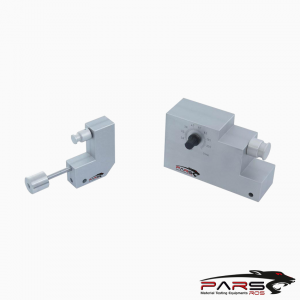

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Reviews (0)

Be the first to review “ASTM D7972 Test Fixture”

You must be logged in to post a review.

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Reviews

There are no reviews yet.