ASTM D8067 Test Fikstürü

ASTM D8067 covers determination of apparent in-plane shear strength and stiffness properties of flat sandwich constructions with composite face sheets.

Please Contact With Us For More Information

- Açıklama

- Değerlendirmeler (0)

- TEKNİK ÖZELLİKLER

Açıklama

Açıklama

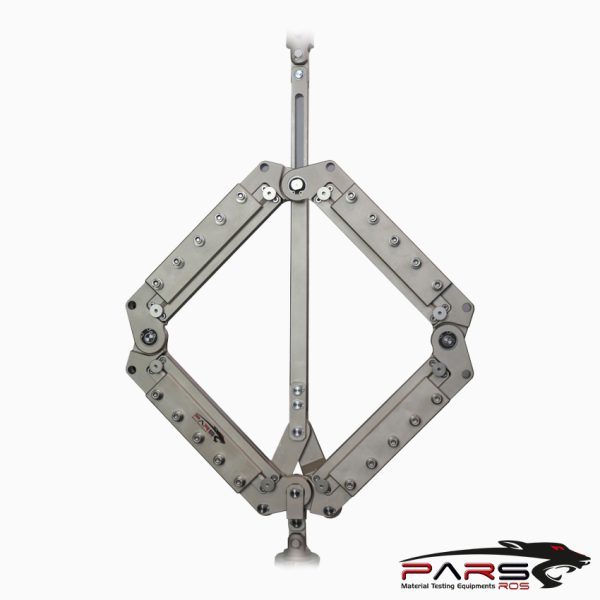

ASTM D8067 – Standard Test Method for In-Plane Shear Properties of Sandwich Panels Using a Picture Frame Fixture

ASTM D8067 covers determination of apparent in-plane shear strength and stiffness properties of flat sandwich constructions with composite face sheets.

Permissible core material forms include those with continuous bonding surfaces (such as balsa wood and foams) as well as those with discontinuous bonding

surfaces (such as honeycomb).

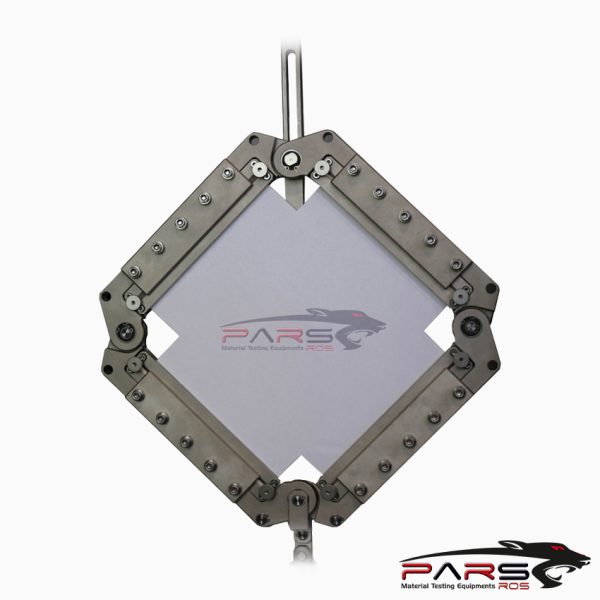

The square test specimen with corner notches is mechanically fastened to a pinned metal frame along each edge.

The frame is loaded in uni-axial tension which produces tensile forces in the frame elements at a 45° angle to the applied tension.

These tensile forces act along the edges of the specimen to cause a state of predominately shear stress to transfer the applied force through the specimen.

Procedure A uses a specimen without edge doublers;

Procedure B uses a specimen with four discrete edge doublers;

Procedure C uses a specimen with a continuous edge doubler.

ASTM D8067 / Significance and Use

In-plane shear loading tests on flat sandwich constructions may be conducted to determine the sandwich panel in-plane shear stiffness, the face sheets’ in-plane

strength, the core shear instability strength, or panel buckling response.

This test method can be used to produce face sheet strength data for structural design allowables, material specifications, and research and development

applications;

it may also be used as a quality control test for bonded sandwich panels.

ASTM D8067 / Apparatus

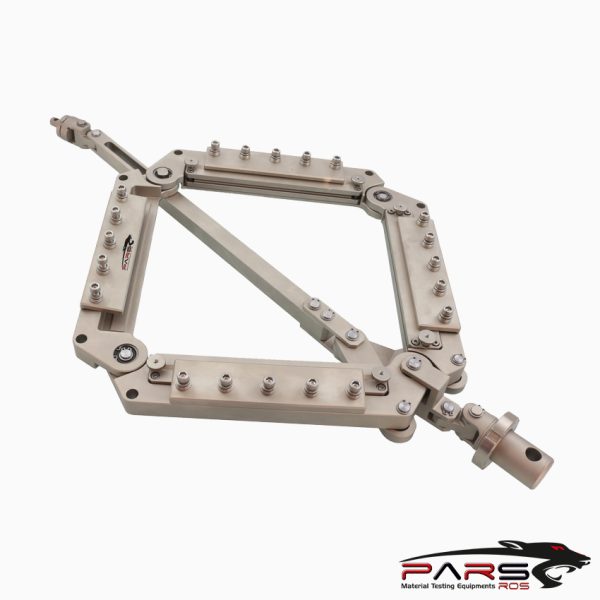

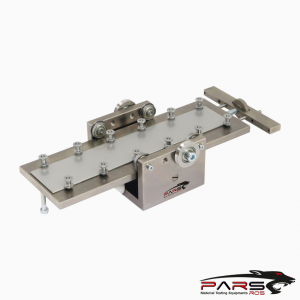

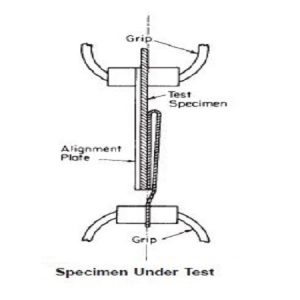

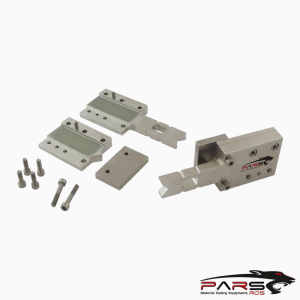

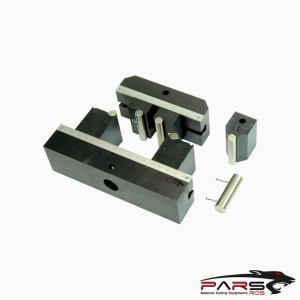

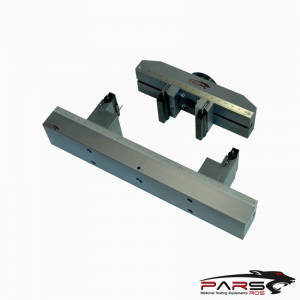

ASTM D8067 / Loading Fixture—The loading fixture shall be selfaligning and shall not apply eccentric forces.

A satisfactory type of apparatus for testing relatively thin face sheet panels.

It consists of a steel frame with four corner pins and 40 panel mounting fastener holes.

Before using the test fixture, a stress analysis of the entire fixture should be performed, using a conservative estimated failure load for the panel to be tested.

ASTM D8067 / Testing Machine—The testing machine shall be in accordance with Practices ASTM E4 and shall satisfy the following requirements:

Testing Machine Configuration—The testing machineshall have both an essentially stationary head and a movable head.

Drive Mechanism—The testing machine drive mechanism shall be capable of imparting to the movable head a controlled velocity with respect to the stationary

head

ASTM D8067 / Summary of Test Method

This test method consists of subjecting a square panel of sandwich construction to a set of forces along the panel edges such that the applied force is transferred

through the panel via a state of predominately shear stresses.

The tensile forces are applied using a picture-frame loading fixture.

By placing two strain gage rosettes in the center of the specimen, the apparent shear stress-strain response of the panel can be measured.

Out-of-plane panel deflection can be measured to assist in detecting panel buckling.

It is noted that engineering shear strain, as opposed to tensorial shear strain, is used throughout this standard.

NOTE 1—Tensorial shear strain may be used in analysis and reporting of results from tests using this standard, but requires the appropriate inclusion of the factor of 2,

and clear documentation shall be made in the test report.

Procedure A uses a specimen without edge doublers.

Procedure B uses a specimen with four discrete edge doublers; the data analysis for this procedure assumes that the doublers do not carry significant shear force.

Procedure C uses a specimen with a continuous edge doubler; the data analysis for this procedure assumes that the doublers carry some shear force, and

a correction is made to the applied force before calculating the shear stress in the panel.

The acceptable failure modes are face sheet fracture, face sheet dimpling, face sheet wrinkling or core shear instability.

Failure of the sandwich core-to-face sheet bond preceding one of the previous listed modes is not an acceptable failure mode.

Failure originating at the panel corner notches is not an acceptable failure mode.

Buckling of the panel prior to face sheet or core failure is not an acceptable failure mode, unless otherwise specified as an acceptable response by the test requestor.

The test specimen face sheet thicknesses, core thickness, core material and adhesive material must be selected to avoid the unacceptable failure modes.

*** Before conducting ASTM D8067 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Değerlendirmeler (0)

“ASTM D8067 Test Fikstürü” için yorum yapan ilk kişi siz olun

Değerlendirme yazabilmek için oturum açmalısınız.

Değerlendirmeler

Henüz değerlendirme yapılmadı.