ASTM D876 – Polymer Tube Tensile Test

ASTM D876 – This test method covers the testing of general-purpose (Grade A), low-temperature (Grade B), and high-temperature (Grade C)2 nonrigid vinyl chloride

polymer tubing, or its copolymers with other materials, for use as electrical insulation.

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- TEKNİK ÖZELLİKLER

Açıklama

ASTM D876 – Polymer Tube Tensile Test

ASTM D876 – This test method covers the testing of general-purpose (Grade A), low-temperature (Grade B), and high-temperature (Grade C)2 nonrigid vinyl

chloride polymer tubing, or its copolymers with other materials, for use as electrical insulation.

For the purpose of these test methods nonrigid tubing shall be tubing having an initial elongation in excess of 100 % at break.

NOTE 1: These test methods are similar but not identical to those in IEC 60684–2.

ASTM D876 – Process

ASTM D876 is extremely similar to ASTM D2671 for Heat-Shrinkable Tubing.

Both tests specify several types of tests for nonrigid PVC tube and pipes.

The tensile test references other standards such as D412 and requires the use of specific sample specimen dies.

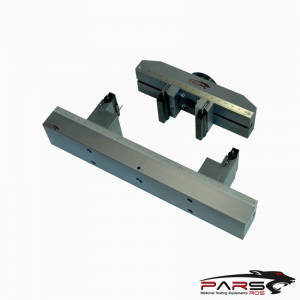

Tubes can also be tested as long as their psi is below a certain threshold. Another test under D876, the heat-shrink test, uses a special type of mandrel which is

inserted into the end of the pipe to maintain its inner diameter (ID).

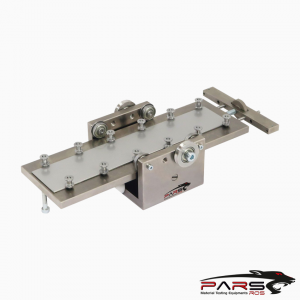

The third test of note is a peel test, wherein an adhesive tape or adhesive layer of tubing is peeled away from the core tube utlizing a special fixture.

ASTM D876 – Geometry

The ID and OD are the two most critical factors. By subtracting OD minus ID, a cross sectional area can be calculated. The ID value is important in order to specify

the size of the mandrel.

The peel test fixture is a different apparatus. The tube is held perpendicular in the machine by a specialized fixture.

*** Before conducting ASTM D876 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

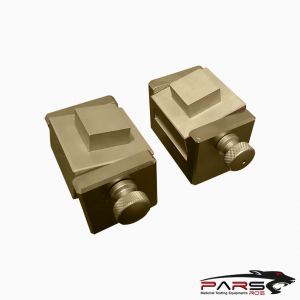

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Referenced Documents

ASTM Standards

ASTM – D149 Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at Commercial Power Frequencies

ASTM – D257 Test Methods for DC Resistance or Conductance of Insulating Materials

ASTM – D374 Test Methods for Thickness of Solid Electrical Insulation (Metric) D0374_D0374M

ASTM – D412 Test Methods for Vulcanized Rubber and Thermoplastic ElastomersTension

ASTM – D471 Test Method for Rubber PropertyEffect of Liquids

ASTM – D746 Test Method for Brittleness Temperature of Plastics and Elastomers by Impact

ASTM – D1000 Test Methods for Pressure-Sensitive Adhesive-Coated Tapes Used for Electrical and Electronic Applications

ASTM – D1711 Terminology Relating to Electrical Insulation

ASTM – D5032 Practice for Maintaining Constant Relative Humidity by Means of Aqueous Glycerin Solutions

ASTM – D8355 Test Methods for Flammability of Electrical Insulating Materials Used for Sleeving or Tubing

ASTM – E104 Practice for Maintaining Constant Relative Humidity by Means of Aqueous Solutions

ASTM – E176 Terminology of Fire Standards