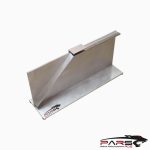

ASTM D905 Test Fixture

ASTM D905 covers the determination of the comparative shear strengths of adhesive bonds used for bonding wood and other similar materials, when tested on

a standard specimen under specified conditions of preparation, conditioning, and loading in compression.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFCATIONS

Description

Description

ASTM D905 − Standard Test Method for Strength Properties of Adhesive Bonds in Shear by Compression Loading

ASTM D905 covers the determination of the comparative shear strengths of adhesive bonds used for bonding wood and other similar materials, when tested on

a standard specimen under specified conditions of preparation, conditioning, and loading in compression.

ASTM D905 is intended primarily as an evaluation of adhesives for wood.

ASTM D905 / Significance and Use

It cannot be assumed that this test method measures the true shear strength of the adhesive bond.

Many factors interfere or bias the measurement including the strength of the wood, the specimen, the shear tool designs themselves, and the rate of loading.

Wood failure is very common in joints made with strong adhesives.

Although high wood failure is normally desired, when it occurs the measured strength is lower than the true

Stress concentrations at the notches of the specimen tend to lower the measured strength.

In a similar test for the shear strength of solid wood, Test Methods ASTM D143, these effects are self correcting so that the measured strength is close to the

true shear strength of the wood.

By analogy the same may be true in this test method, however, other factors are also involved and may alter the relationship.

The rate of loading affects the strength of an adhesive bond according to the adhesive’s rheological properties.

The more viscoelastic or plastic the adhesive, the greater effect.

Thermosetting adhesives like urea- and phenol-formaldehyde are elastic.

Their bond strengths can be measured over a range of loading rate from 0.038 to 1.27 cm/min [0.015 to 0.5 in./min] with no apparent affect.

Thermoplastic adhesives like polyvinyl acetate, hot melts, and elastomer-based adhesives exhibit a broad range of elastic, viscoelastic, and plastic behaviors.

Their bond strengths will be affected to varying degrees by changing the loading rate. Generally, increasing the rate, increases the measured strength.

ASTM D905 method is suitable for product research and development, qualifying adhesives in accordance with certain product or performance specifications,

and monitoring bonding process control.

This test method may be suitable for comparing and selecting adhesives, however, such comparisons must be made with caution since the measured strength of

some adhesives may be different in different types of joints.

Strength values obtained by this test method are not suitable as design shear strengths values without adjustment by certain engineering design factors.

ASTM D905 /Apparatus

The testing machine shall have a capacity of not less than 6810 kg (15 000 lb) in compression and shall be fitted with a shearing tool containing a self-aligning seat

to ensure uniform lateral distribution of the load.

The machine shall be capable of maintaining a uniform rate of loading such that the load may be applied with a continuous motion of the movable head to

maximum load at a rate of 5 mm (0.20 in.)/min with a permissible variation of 625 %.

The shearing tool has been found satisfactory.

The testing machine shall be located in an atmosphere such that the moisture content of the specimens developed under the conditions.

ASTM D905 / Preparation of Test Joints

Hard maple blocks (Acer saccharum or Acer nigrum), having a minimum specific gravity of 0.65 based on oven-dry weight and volume shall be selected

These blocks shall be of straight grain and free from defects including knots, birdseye, short grain, decay, and any unusual discolorations within the

shearing area.

The blocks shall be of suitable size preferably so that five test specimens may be cut from one test joint.

Blocks approximately 19 by 63.5 by 304 mm (3⁄4 by 21⁄2 by 12 in.) have been found to be satisfactory for this purpose.

The grain direction shall be parallel to the longest dimension of the block.

The blocks shall be at the equilibrium moisture content recommended by the manufacturer of the adhesive.

In the absence of such recommendation, the moisture content shall be from 10 to 12 % based on oven-dry weight as determined on representative samples in

accordance with the “Moisture Determination” section of Test Methods ASTM D143.

The blocks shall be surfaced, just prior to bonding, preferably with a hand-feed jointer, and the blocks weighed and assembled in pairs so that blocks of

approximately the same specific gravity are bonded together.

The surfaces shall remain unsanded and shall be free from dirt.

NOTE —A method for selecting maple blocks of satisfactory specific gravity is described in the Appendix to this method.

For referee tests, the specific gravity of blocks may be determined in accordance with the procedure described in the “Specific Gravity and Shrinkage in

Volume” section of Test Methods ASTM D143.

The adhesive shall be prepared and applied to the blocks in accordance with the procedure recommended by the manufacturer of the adhesive.

The adhesive-coated blocks shall then be assembled and pressed, likewise in accordance with the recommendations of the manufacturer of the adhesive

ASTM D905 / Preparation of Specimens

Cut the specimens so that the grain direction is parallel to the direction of loading during test.

Take care in preparing the test specimens to make the loaded surfaces smooth and parallel to each other and perpendicular to the height.

Take care also in reducing the lengths of the laminations to 44.4 mm (13⁄4 in.) to ensure that the saw cuts extend to, but not beyond, the bond line.

Measure the width and length of the specimen at the bond line to the nearest 0.25 mm (0.010 in.) to determine the shear area.

Retain specimens in the conditioning atmosphere described in Section 8 until tested, except during the cutting operations. 10.

Procedure Place the test specimen in the shearing tool so that the load may be applied

Apply the loading with a continuous motion of the movable head at a rate of 5 mm (0.20 in.)/min to failure

*** Before conducting ASTM D905 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Reviews (0)

Be the first to review “ASTM D905 Test Fixture”

You must be logged in to post a review.

TECHNICAL SPECIFCATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Reviews

There are no reviews yet.