ASTM E290 – Standard Test Methods for Bend Testing of Material for Ductility

ASTM E290 – Bend Test on Metal Samples

ASTM E290 – This test method covers bend testing for ductility of materials.

Included in the procedures are four conditions of constraint on the bent portion of the specimen;

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM E290 – Standard Test Methods for Bend Testing of Material for Ductility

ASTM E290 – Bend Test on Metal Samples

ASTM E290 – This test method covers bend testing for ductility of materials.

Included in the procedures are four conditions of constraint on the bent portion of the specimen; a guided-bend test using a mandrel or plunger of defined

dimensions to force the mid-length of the specimen between two supports separated by a defined space; a semi-guided bend test in which the specimen is bent,

while in contact with a mandrel, through a specified angle or to a specified inside radius (r) of curvature, measured while under the bending force;

a free-bend test in which the ends of the specimen are brought toward each other, but in which no transverse force is applied to the bend itself and

there is no contact of the concave inside surface of the bend with other material; a bend and flatten test, in which a transverse force is applied to the

bend such that the legs make contact with each other over the length of the specimen.

After bending, the convex surface of the bend is examined for evidence of a crack or surface irregularities.

If the specimen fractures, the material has failed the test. When complete fracture does not occur, the criterion for failure is the number and size of cracks

or surface irregularities visible to the unaided eye occurring on the convex surface of the specimen after bending, as specified by the product standard.

Any cracks within one thickness of the edge of the specimen are not considered a bend test failure.

Cracks occurring in the corners of the bent portion shall not be considered significant unless they exceed the size specified for corner cracks in the product standard.

ASTM E290 – Geometry

The 3 point bend test can be performed on different sized samples.

There are several key paramaters including the sample thickness (T), and the sample width (W). Also, the radius (R) of the bending fin or loading nose,

and the distance (C) between the two loading points are important.

In cylindrical samples the Diameter (D) of the rod is used instead of the Thickness (T) of the sheet.

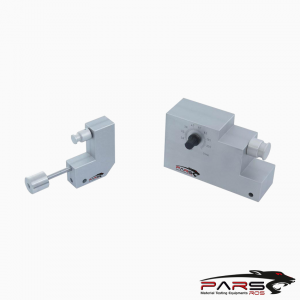

Solution

PARSROS offers an adjustable bend fixtue which can be used in conjunction with aUniversal testing machine.

The distance (C) between the two loading supports is adjustable on the fixture.

This feature allows testing to be done on different sized sample specimens. The sample is bent using a Universal Testing Machine.

Analysis

Test analysis for this type of bend testing is rather simple. Measuring the peak load that the sample was able to withstand before bending is the main criteria.

Similar Specifications

ASTM D790 – Plastics Bend Test

ASTM D5459 – Plane Strain Bend Test

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests that are

accurate and repeatable.

TECHNICAL SPECIFICATIONS

Please contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations