ASTM E561 Test Fikstürü

ASTM E561 covers the determination of the resistance to fracture of metallic materials under Mode I loading at static rates using either of the following notched

and precracked specimens:

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- Değerlendirmeler (0)

- TEKNİK ÖZELLİKLER

Açıklama

ASTM E561- Standard Test Method for KR Curve Determination

ASTM E561 covers the determination of the resistance to fracture of metallic materials under Mode I loading at static rates using either of the following notched

and precracked specimens:

The middle-cracked tension M(T) specimen or the compact tension C(T) specimen.

A KR curve is a continuous record of toughness development (resistance to crack extension) in terms of KR plotted against crack extension in the specimen as a

crack is driven under an increasing stress intensity factor, K. (1)

Materials that can be tested for KR curve development are not limited by strength, thickness, or toughness, so long as specimens are of sufficient size to remain

predominantly elastic to the effective crack extension value of interest.

Specimens of standard proportions are required, but size is variable, to be adjusted for yield strength and toughness of the materials.

Only two of the many possible specimen types that could be used to develop KR curves are covered in this method.

The test is applicable to conditions where a material exhibits slow, stable crack extension under increasing crack driving force, which may exist in relatively tough

materials under plane stress crack tip conditions

ASTM E561 / Apparatus

Testing Machine—Machines used for KR curve testing shall conform to the requirements of Practices ASTM E4.

The forces used in determining KR values shall be within the verified force application range of the testing machine as defined in Practices ASTM E4.

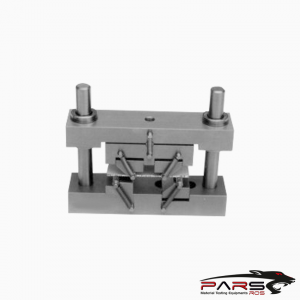

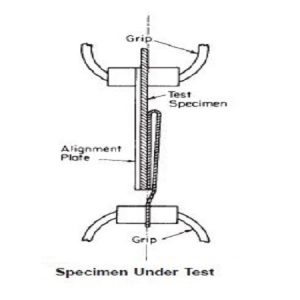

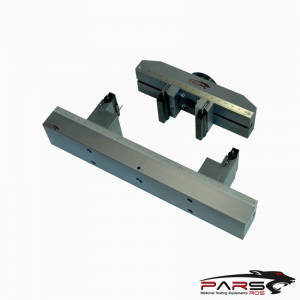

ASTM E561 / Grips and Fixtures for Middle-Cracked Tension (M(T))

Specimens—In middle-cracked tension specimens, the grip fixtures are designed to develop uniform stress distribution in the central region of the specimen.

Single pin grips can be used on specimens less than 305 mm (12 in.) wide if the specimen is long enough to ensure uniform stress distribution in the crack plane

For specimens wider than 305 mm (12 in.), multiple-bolt grips or wedge grips that apply a uniform displacement along the entire width of the specimen end shall be

used .

Other gripping arrangements can be used if the appropriate stress intensity factor and compliance relationships are verified and used.

Grips should be carefully aligned to minimize the introduction of bending strain into the specimen.

Pin or gimbal connections can be located between the grips and testing machine to aid the symmetry of loading.

If extra-heavy-gauge, high-toughness materials are to be tested, the suitability of the grip arrangement may be checked using the AISC Steel Construction Manual.

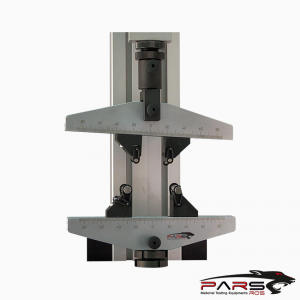

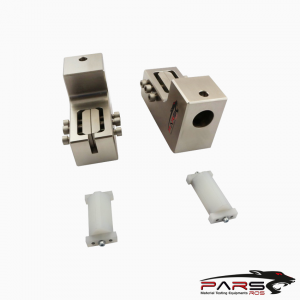

ASTM E561 / Grips and Fixtures for Compact Tension (C(T))

Specimens—The grips and fixtures described in Test Method ASTM E399 are recommended for KR curve testing where C(T)-type specimens are loaded in tension.

ASTM E561 / Summary of Test Method

During slow-stable fracturing, the developing crack extension resistance KR is equal to the applied stress intensity factor K.

The crack is driven forward by continuously or incrementally increasing force or displacement.

Measurements are made periodically for determination of the effective crack size and for calculation of K values, which are individual data points that define the

KR curve for the material under those test conditions.

The crack starter is a low-stress-level fatigue crack.

The method covers two techniques for determination of effective crack size:

(1) direct measurement of the physical crack size which is then adjusted for the developing plastic zone size, and

(2) compliance measurement techniques that yield the effective crack size directly.

Methods of measuring crack extension and of making plastic-zone corrections to the physical crack size are prescribed.

Expressions for the calculation of crack-extension force KR are given.

Criteria for determining if the specimen conditions are predominantly elastic are provided.

*** Before conducting ASTM E561 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Bir yanıt yazın

Yorum yapabilmek için oturum açmalısınız.