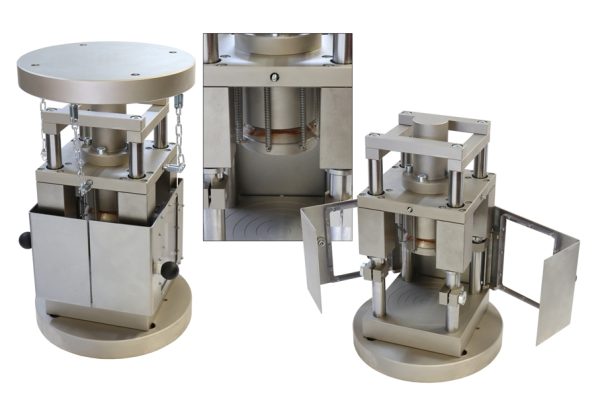

ASTM E9 Test Fixture

ASTM E9 covers the apparatus, specimens, and procedure for axial-force compression testing of metallic materials at room temperature

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

ASTM E9 – Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature

ASTM E9 covers the apparatus, specimens, and procedure for axial-force compression testing of metallic materials at room temperature

NOTE —For compression tests at elevated temperatures, see Practice ASTM E209.

ASTM E9 / Significance and Use

Significance—The data obtained from a compression test may include the yield strength, the upper yield strength, the Young’s modulus, the stress-strain curve, and

the compressive strength .

In the case of a material that does not fail in compression by a shattering fracture, compressive strength is a value that depends on total strain and specimen geometry.

Use—Compressive properties are of interest in the analyses of structures subject to compressive forces or bending moments or both and in the analyses of metal

working and fabrication processes that involve large compressive deformation such as forging and rolling.

For brittle or nonductile metals that fracture in tension at stresses below the yield strength, compression tests offer the possibility of extending the strain range of the

stress-strain data.

While the compression test is not complicated by necking as is the tension test for certain metallic materials, buckling and barreling can complicate results and

should be minimized

ASTM E9 / Apparatus

Testing Machines—Machines used for compression testing shall conform to the requirements of Practices ASTM E4.

For universal machines with a common test space, calibration shall be performed in compression.

The bearing surfaces of the heads of the testing machine shall be parallel at all times with 0.0002 in./in. (m/m) unless an alignment device

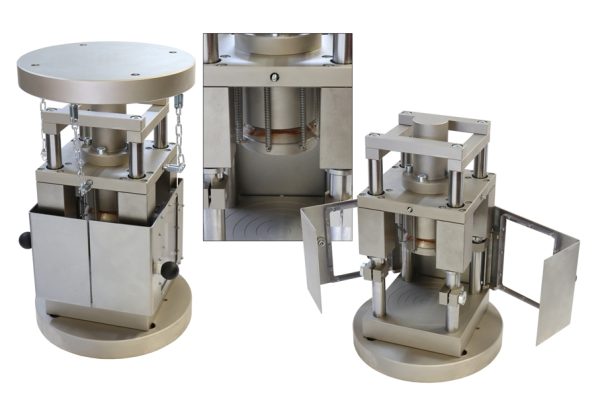

ASTM E9 / Bearing Blocks

Both ends of the compression specimen shall bear on blocks with surfaces flat and parallel within 0.0002 in./in. (m/m).

Lack of initial parallelism can be overcome by the use of adjustable bearing blocks

NOTE : The blocks shall be made of, or faced with, hard material.

Current laboratory practice suggests the use of tungsten carbide when testing steel and hardened steel blocks (55 HRC or greater) and when testing nonferrous

materials such as aluminum, copper, etc.

The specimen must be carefully centered with respect to the testing machine heads or the subpress

NOTE : It should be remembered that the object of an adjustable bearing block is to give the specimen as even a distribution of initial load as possible.

An adjustable bearing block cannot be relied on to compensate for any tilting of the heads that may occur during the test.

The bearing faces of adjustable bearing blocks that contact the specimen shall be made parallel before the load is applied to the specimen.

Another arrangement involving the use of a spherical-seated bearing block that has been found satisfactory for testing material other than in sheet form .

It is desirable that the spherical-seated bearing block be at the upper end of the test specimen (for specimens tested with the load axis vertical).

The spherical surface of the block shall be defined by a Radius having its point of origin in the flat surface that bears on the specimen.

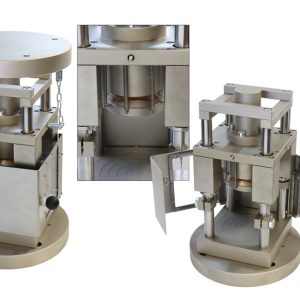

ASTM E9 /Alignment Device/Subpress

Axial alignment. The design of the device or subpress is largely dependent on the size and strength of the specimen.

It must be designed so that the ram (or other moving parts) does not jam or tilt the device or the frame of the machine as a result of loading.

The bearing blocks of the device shall have the same requirements for parallelism and flatness

The primary requirements of all alignment devices are that the load is applied axially, uniformly, and with negligible “slip-stick” friction.

ASTM E9 / Compression Testing Jigs—In testing thin specimens, such as sheet material, some means should be adopted to prevent the specimen from buckling

during loading.

This may be accomplished by using a jig containing sidesupport plates that bear against the wide sides of the specimen.

The jig must afford a suitable combination of lateral-support pressure and spring constant to prevent buckling, but without interfering with axial deformation of

the specimen.

Although suitable combinations vary somewhat with variations in specimen material and thickness, testing temperatures, and accuracy of alignment, acceptable

results can be obtained with rather wide ranges of lateral-support pressure and spring constant.

Generally, the higher the spring constant of the jig, the lower the lateral-support pressure that is required.

Proper adjustments of these variables should be established during the qualification of the equipment

It is not the intent of these methods to designate specific jigs for testing sheet materials, but merely to provide a few illustrations and references to jigs that have

been used successfully.

Compression jigs generally require that the specimen be lubricated on the supported sides to prevent extraneous friction forces from occurring at the support points.

ASTM E9 / SPECIAL REQUIREMENTS IN THE DETERMINATION OF THE COMPRESSIVE STRENGTH OF CEMENTED CARBIDES

ASTM E9 / Bearing Blocks— Cemented carbide bearing blocks shall be used.

They shall be of a hardness such that the block faces will not suffer significant permanent deformation during test (suggested hardness of 92 HRA).

ASTM E9 / Bearing Block Preparation—The block diameter shall be at least three times the diameter of the specimen.

Its thickness shall be at least two thirds the block diameter.

Faces of the bearing blocks shall be flat within 60.0002 in./in. (m/m), parallel within 0.0005 in./in. (m/m), and have a surface finish of 8 μin. (0.2 μm)

arithmetic average (aa).

The blocks shall be used in conjunction with devices

*** Before conducting ASTM E9 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Reviews (0)

Be the first to review “ASTM E9 Test Fixture” Cancel reply

You must be logged in to post a review.

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Reviews

There are no reviews yet.