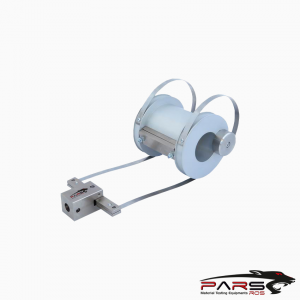

ASTM F1342 Test Fikstürü

ASTM F1342 determines the puncture resistance of aprotective clothing material specimen by measuring the force required to cause a pointed puncture probe

to penetrate through the specimen.

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- Değerlendirmeler (0)

- TEKNİK ÖZELLİKLER

Açıklama

ASTM F1342 – Standard Test Method for Protective Clothing Material Resistance to Puncture

ASTM F1342 determines the puncture resistance of aprotective clothing material specimen by measuring the force required to cause a pointed puncture probe

to penetrate through the specimen.

This test method describes three protocols that may be used: Method A, Method B, and Method C.

Method A requires the use of Probe A only. The probe used for testing shall be recorded in the test report.

Probe A may be used to measure puncture resistance for the following types of materials:

(1) Elastomeric materials

(2) Textiles

(3) Coated materials

Method B requires the use of Probe B. The probe used for testing shall be recorded in the test report.

Probe B may be used to measure puncture resistance for the following types of materials:

(1) Textiles

(2) Coated materials

NOTE —Probe B is not suited for measuring the puncture resistance of unsupported elastomeric materials.

ASTM F1342 / Significance and Use

This test method evaluates puncture resistance of protective clothing materials which may include plastics or elastomeric films, coated fabrics, flexible materials,

laminates, or textile materials.

This test method is not intended to measure puncture resistance of all types of punctures encountered using protective clothing material.

This test method involves a procedure puncturing specimens.

This test method evaluates puncture resistance of protective clothing materials, specifically for puncture forced on specimens perpendicular to material surface.

There is no supporting structure under the material specimen.

Evaluation of puncture resistance for snag-type puncture should be performed in accordance with Test Method D2582

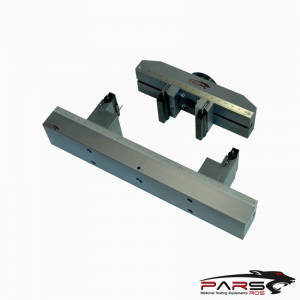

ASTM F1342 / Apparatus

Testing Machine, shall meet the following criteria:

It shall be capable of holding the specimen securely between the two clamps and be capable of straining the specimen with a uniform movement.

A machine capable of providing load versus elongation data until point of rupture shall be used.

The error of the machine shall not exceed 2 % at any reading within its loading range.

It shall be outfitted with a compression cell.

The testing machine may be configured with the compression cell on either the lower or upper arm.

The compression cell shall have a range sufficient enough to penetrate the specimen.

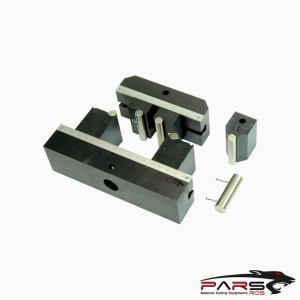

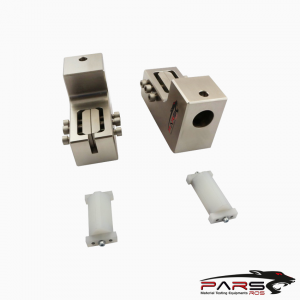

Puncture Probes

Probe A, The puncture probe shall be fabricated from stainless steel with a Rockwell Hardness of not less than 35.

Probe B, The puncture probe shall be fabricated from stainless steel with a Rockwell Hardness of not less than 35

Probe C, The puncture probe shall be fabricated from stainless steel with a Rockwell Hardness of not less than 35.

ASTM F1342 / Summary of Test Method

A material specimen is placed in a stationary support assembly that is in turn affixed to the lower arm of a tension testing machine.

A pointed puncture probe of set dimensions is mounted to the test fixture and the whole assembly is attached to the compression cell of the testing machine.

The puncture probe is moved at a constant velocity until it punctures the material specimen.

The force required to puncture the material specimen is measured by the compression cell.

The elongation (or deflection) of the specimen prior to puncture is also measured.

The reported puncture resistance is the average of twelve test replicates.

*** Before conducting ASTM F1342 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Bir yanıt yazın

Yorum yapabilmek için oturum açmalısınız.