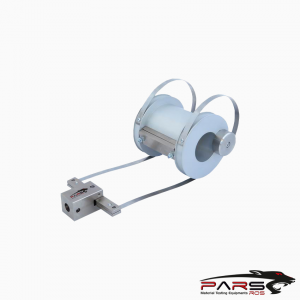

ASTM F732 Test Fikstürü

ASTM F732 describes a laboratory method for evaluating the wear properties of combinations of materials that are being considered for use as bearing surfaces

of human total joint prostheses.

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- Değerlendirmeler (0)

- TEKNİK ÖZELLİKLER

Açıklama

Açıklama

ASTM F732- Standard Test Method for Wear Testing of Polymeric Materials Used in Total Joint Prostheses

ASTM F732 describes a laboratory method for evaluating the wear properties of combinations of materials that are being considered for use as bearing surfaces

of human total joint prostheses.

The body of this test method contains general methods which apply to all types of prosthesis wear applications while individual annexes describe specific wear test

methods and clinical validation criteria tailored to each distinct wear application (for example, linear reciprocating motion, ball-cup (“hip-type”) wear, delamination

wear, etc.). and so forth).

It is the intent of this test method to rank materials, within each wear application, for polymer wear rates under simulated physiological conditions.

It must be recognized, however, that contact geometries and wear motions are simplified using such methods.

This test method, therefore, represents only an initial stage in the full wear characterization of a candidate material.

ASTM F732 / Apparatus and Materials

Orthopaedic Wear Application:

For linear reciprocating wear motion applications, refer to Annex A1.

For fixed-bearing ball-cup (“hip-type”) wear motion applications, refer to Annex A2.

For nominally linear motion delamination wear applications, refer to Annex A3.

ASTM F732 – Annex A1. TEST METHOD FOR LINEAR RECIPROCATING WEAR MOTION APPLICATIONS

The “linear reciprocating wear motion” test method describes a laboratory method for evaluating the friction and wear properties of combinations of materials

that are being considered for use as the bearing surfaces of human total joint replacement prostheses which experience only linear reciprocating

(straight or rotatory) wear motion.

Such applications include hinged knees, other hinged joints, trunnion bearings, axle bearings, some mobile bearing knee applications in which the insert/tibial tray

attachment mechanisms allow for linear motion only, and any other application in which the wear path at any given contact point reciprocates along a fixed line.

Applications which are not relevant to this test method include head/socket articulation in hips and shoulders, fossa/condyle articulation in temporomandibular

joints, liner/shell relative motion in hips, all patellofemoral and femorotibial articulation in knees where internal-external rotation may occur, and tibial insert

/tibial tray relative motion in knees where rotation may occur.

It is the intent of this test method to rank the materials with regard to friction levels and polymer wear rates under simulated physiological conditions.

However, it must be recognized that, since any one design of joint replacement, even within this restricted scope, performs under unique conditions of load, motion,

and contact geometry, there can be no single universally applicable wear screening test.

This test method therefore represents only the first stage in the full characterization of a candidate material.

ASTM F732 / Apparatus

Specimen Chambers—In the case of a multiple specimen machine, the specimens shall be contained in individual isolated chambers to prevent contamination of

one set of specimens with debris from another test specimen.

The chamber shall be made entirely of corrosion-resistant materials such as acrylic plastic and shall be easily removable from the machine for thorough cleaning

between tests.

The wear chambers shall be designed such that the specimen surfaces are immersed in the lubricant for the duration of the test.

Load—The test load of 225 N [50.6 lbf] shall be applied along the longitudinal axis of the polymer specimen, such that the average contact stress is 3.54 MPa [513 psi].

The loading apparatus must be free to follow the specimen as wear occurs, such that the applied load is constant to within 63 % for the duration of the test.

Motion—Relative motion between the specimen and the counterface shall be oscillatory.

The orientation between sliding direction and the lay of the surface roughness in each test should be noted.

It is recommended that the relative orientation of the pin and disk be maintained by suitable specimen-holder keying.

Sliding Speed—Specimens shall be run through a 25 mm stroke at a rate of 1 cycle/s, producing an average sliding speed of 50 mm/s.

Cycle Counter—The machine shall include a cycle counter to record the total number of wear cycles.

Friction—It is recommended that the machine include strain gage instrumentation or other transducers capable of providing a continuous readout of the tangential

(friction) force transmitted across the specimen interface during the test.

*** Before conducting ASTM F732 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Değerlendirmeler (0)

“ASTM F732 Test Fikstürü” için yorum yapan ilk kişi siz olun

Değerlendirme yazabilmek için oturum açmalısınız.

Değerlendirmeler

Henüz değerlendirme yapılmadı.