Automatic Specimen Grinding Machine

STANDARDS : EN 12390-1, 12390-3, 12504-1; ASTM C 31, C39, C42, C192, C617

Automatic Specimen Grinding Machine provides fast grinding of cylinder specimen ends to obtain plane and parallel surfaces

according to EN and ASTM standards.

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

| Product Code | Product Description |

| PRS-CASGM100 | Automatic Specimen Grinding Machine |

| PRS-CASGM102 | Grinding Wheel |

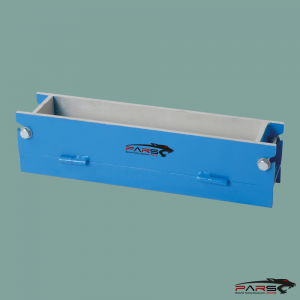

| PRS-CASGM104 | Water Restraint Panel Set for Cylinder Specimens |

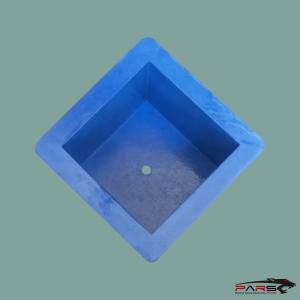

| PRS-CASGM107 | Cradle and Water Restraint Panel for three units of 100 mm Cube specimens |

| PRS-CASGM108 | Water Restraint Panel for Ø160 mm Cylinder specimen |

| PRS-CASGM109 | Cradle and Water Restraint Panel for one unit of 150 mm Cube Specimens |

| PRS-CASGM164 | Water Tank with Filtration and Circulation System |

Automatic Specimen Grinding Machine

STANDARDS : EN 12390-1, 12390-3, 12504-1; ASTM C 31, C39, C42, C192, C617

ParsRos Automatic Specimen Grinding Machine provides fast grinding of cylinder specimen ends to obtain plane and parallel surfaces

according to EN and ASTM standards.

Three units of Ø38 to 100 mm or two units of Ø150-160 mm concrete cylinders ends and three units of 100 mm or one unit of 150 mm concrete cubes faces can be

ground simultaneously with the suitable cradle and water restraint panel.

The lenght of the any specimen must be longer than 110 mm.

According to ASTM and EN standards, the planeness accuracy of grinded surfaces of concrete compression test specimens should be 0.05 mm. and also the deviation of

perpendicularity of the side with reference to the end faces should be 0,5°.

The equipment has selectable advance grinding time functionality by user from 50 to 400 seconds. Optimum grinding time per end of all type specimens is 90 to 120 seconds.

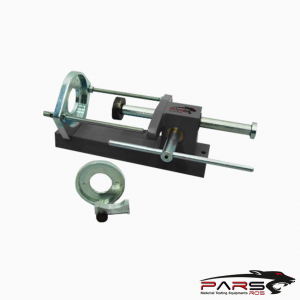

The cradle which specimens are fixed on has automatic bidirectional radial displacement ability.

The safe and ergonomic design prevents the user to exposure to water and dust and provides easy access to the water inlet and outlet.

Specimen cradles and water restraint panels can easily be installed without the need for any assembly.

Mobility of the machine is achieved with the help of the integral wheels, and all components of the system can be safely accessed for easy maintenance.

The frame is manufactured from aluminum to obtain a lighter weight and the stainless steel exterior shell assures resistance to corrosion.

Water Restraint Panel Set for Cylinder consist of panels for Ø150 mm, Ø100 mm and Ø50 mm specimens.

*** For different sized cylindrical specimens, the water restraint panel should be ordered seperately.

The cradle and the water restraint panels should be ordered seperately for 100mm and 150mm cubic specimens.

Filtration and Circulation System Water Tank is designed to save the amount of water used during the etching process in automatic grinding machines

The Automatic Grinding Machine is supplied complete with;

Grinding Wheel for concrete specimens

Cradle for Ø:38mm to100 mm cylindrical specimens

Cradle for Ø:150mm to160 mm cylindrical specimens (connected to the machine)

Water restraint panel set (Consist of panels for Ø150, Ø100 and Ø50 mm specimens)

Reviews (0)

Be the first to review “Automatic Specimen Grinding Machine”

You must be logged in to post a review.

TECHNICAL SPECIFICATIONS

| The Preparation of Concrete

Cylinder Test Specimen for Compressive Strength Test |

EN 12390-1, 12390-3

ASTM C31, C39, C192, C617 |

The maximum tolerance on the flatness of the potential load bearing surfaces (the ends of compression test specimens) is 0.002 in. [0.050 mm]

The deviation of perpendicularity of the side, with reference to the end faces is 0,5O |

| The Preparation of Drilled

Concrete Cores Specimen for Compressive Strength Test |

EN 12504-1, 12390-1, 12390-3 ASTM C42, C397 |

Reviews

There are no reviews yet.