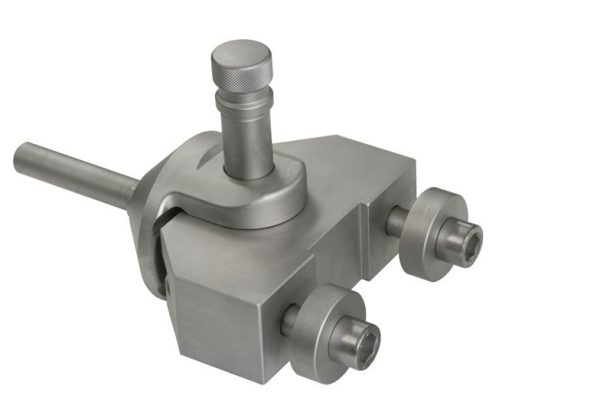

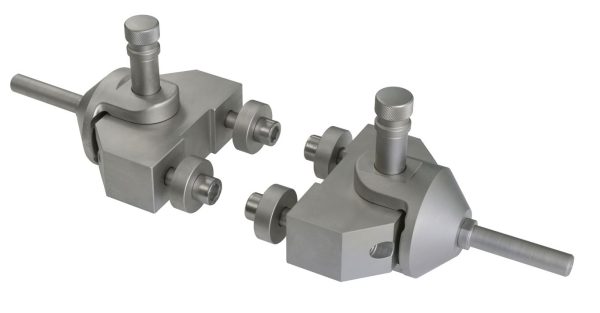

AWS D8.9M Test Fixture

AWS D8.9M – This document contains several standardized test methods designed to evaluate the resistance spot welding behavior of coated and uncoated

sheet steels in a laboratory environment.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

AWS D8.9M Test Methods for Evaluating the Resistance Spot Welding Behavior of Automotive Sheet Steel Materials

AWS D8.9M – This document contains several standardized test methods designed to evaluate the resistance spot welding behavior of coated and uncoated

sheet steels in a laboratory environment.

AWS D8.9M / The test methods allow for uniform testing of automotive sheet steels to determine the following:

(1) The effect of the interaction between a sheet steel’s coating (metallic, nonmetallic, or both) and the welding electrodes on electrode deterioration and

weld size/quality behavior over an extended number of welds

(2) Current levels and current range

(3) Mechanical properties of welds at different weld sizes and hold times

(4) Metallurgical and hardness properties of welds

(5) The effects of sheet lubricants, conductive paints, or other surface treatment on current break-through

(6) The robustness of a grade of steel to variations in key welding process variables

The test methods are intended for application in a laboratory environment to characterize certain aspects of the welding behavior of sheet steel products under

controlled experimental conditions.

They are not intended to simulate production welding practices or to predict welding performance of a given grade of steel in production operations.

The test methods and parameters are designed to be used for sheet steels ranging in thickness from 0.5 mm to 4.0 mm.

The tests may be used for sheet steel materials of all yield strengths typically used in automotive applications. In the endurance test, a minimum of two tests per

material is recommended to obtain an accurate assessment.

The endurance test was developed for low strength (tensile strength less than or equal to 300 MPa) coated steels of lighter gauges.

This test is normally used for coated steels with tensile strength less than or equal to 500 MPa and gauges less than 1.2 mm.

The weld property tests are designed primarily for gauges of 1.2 mm and heavier.

The specific type and number of tests required shall be at the discretion of the specifying party.

While the test methods were developed to compare the welding behavior of different steel grades, they can be judiciously applied to evaluate other aspects of

welding behavior.

Not all of the above mentioned tests are required to establish the resistance spot welding behavior of a given grade of steel.

*** Before conducting AWS D8.9M , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations