BOEING BSS 7260 Test Fikstürü

BOEING BSS 7260 is used for testing composite materials under uniaxial compression.

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- Değerlendirmeler (0)

- TEKNİK ÖZELLİKLER

Açıklama

Açıklama

BOEING BSS 7260 COMPRESSIVE PROPERTIES OF RIGID PLASTICS

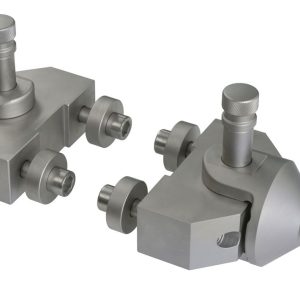

ASTM D695 (BOEING BSS 7260) TESTING FIXTURE

BOEING BSS 7260 is used for testing composite materials under uniaxial compression.

The flat piece is a load plate made of hardened steel, to be interposed between the upper protrusion of the specimen and the load floor of the test machine,

to protect the load plate.

There is actually no ASTM standard governing the Modified D 695 Compression Test Method.

ASTM Standard D 695, originally published in 1942, is intended primarily for unreinforced plastics, as its title implies), using an untabbed, dog-boned, flat specimen.

The Modified D 695 Compression Test Method is defined in Boeing documents, and in SACMA Recommended Test Method SRM 1R-94.

The straight-sided test specimen is 3.18″ long and 0.5″ wide, the thickness depending upon the material being tested.

Is typically used, for a unidirectional composite, a thickness on the order of 0.040″.

Specimens used to determine compressive strength are tabbed on each end, typically with glass fabric/epoxy tabbing material.

The gage length (distance between tabs) is specified to be 0.188″. Because of this very short gage length, it is impractical to mount instrumentation to

measure strains.

*** Before conducting BOEING BSS 7260 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Değerlendirmeler (0)

“BOEING BSS 7260 Test Fikstürü” için yorum yapan ilk kişi siz olun

Değerlendirme yazabilmek için oturum açmalısınız.

Değerlendirmeler

Henüz değerlendirme yapılmadı.