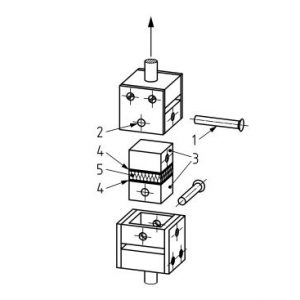

BS EN 392 Test Fixture

BS EN 392 – This standard specifies a method for measuring the shear strength of the glue line parallel to the direction of grain.

The standard is applicable in the field of continuous quality control of the glue line.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

BS EN 392 Glued Laminated Timber — Shear Test of Glue Lines

BS EN 392 – This standard specifies a method for measuring the shear strength of the glue line parallel to the direction of grain.

The standard is applicable in the field of continuous quality control of the glue line.

Shear Test of Glue Lines

Principle A shear stress is applied at the glue line until failure occurs.

Testing machine

A calibrated testing machine capable of applying a compressive force to the shearing tool, referred to in

The accuracy of measuring the maximum load shall be better than ± 3 %.

Shearing tool

The cylindrical bearing shall be self-aligning so that the test piece is loaded at the end grain with a stress field uniform in the width direction.

Preparation of test pieces

Test pieces Special care shall be taken in preparing the test pieces to ensure that the loaded surfaces are smooth and parallel to each other and perpendicular to the grain direction.

Sampling

Test bars shall be cut from the full cross-sectional specimens as described in EN 386.

At least three glue lines in each of the lower, middle and upper part shall be tested. If there are less than 10 laminations all glue lines shall be tested

*** Before conducting BS EN 392 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Reviews (0)

Be the first to review “BS EN 392 Test Fixture”

You must be logged in to post a review.

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Reviews

There are no reviews yet.