Concrete Pipe Compression Testing Machine

STANDARDS : EN 1916, ASTM C301, C497

PARSROS Concrete Pipe Compression Testing Machines are specially designed for Crushing Tests on Sewer and Drain Pipes, Concrete Pipes,

Fittings, according to EN 1916 ,ASTM C301, C497 for Diameters up to 2000 mm or more.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

| Product Code |

Product Description |

| PRS-BCPCM60 | Concrete Pipe Compression Testing Machine,600 kN, 220-240 V 50/60 Hz |

| PRS-BCPCM60-1 | Concrete Pipe Compression Testing Machine,600 kN, 110 V 60 Hz |

| PRS-BCPCM100 | Concrete Pipe Compression Testing Machine,1000 kN, 220-240 V 50/60 Hz |

| PRS-BCPCM100-1 | Concrete Pipe Compression Testing Machine,1000 kN, 110 V 60 Hz |

Concrete Pipe Compression Testing Machine

STANDARDS : EN 1916, ASTM C301, C497

PARSROS Concrete Pipe Compression Testing Machines are specially designed for Crushing Tests on Sewer and Drain Pipes, Concrete Pipes,

Fittings, according to EN 1916 ,ASTM C301, C497 for Diameters up to 2000 mm or more.

The frames are rigid 2- or 4-column constructions with superior axial and lateral stiffness and are precision aligned.

Integrated in the crosshead is a double acting actuator in servo-quality.

The actuator has anti-rotation system to prevent the natural tendency of the actuator to rotate.

With either precision pressure transducer or load cell and optionally displacement transducer for force and displacement closed loop control.

The rectangular shaped top bearer is detachable from the actuator and the bottom bearer is V-shaped with an included angle of 150°.

The system does not permit rotation at horizontal plane of the top bearer but allows it at vertical plane of a minimum value of +-8°.

*** As option 3- and 4-point bending accessories are available.

Available with standard control console in connection with servo valve and digital controller,

PC running building material testing software and printer for fully automatic test procedure in closed loop mode.

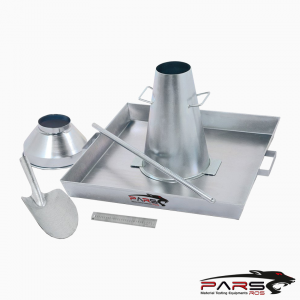

Options and Accessories

Hydraulic crosshead adjustment – passive fastening for easy positioning if the specimens have varying diameters

V-prisms support

Bending Apparatus

Measuring and controlling equipment for electronic piston stroke

Graphic LCD display

High resolution

Backlight function

CPU card by microprocessor 32 bit ARM risk architecture

For automatic load, displacement or deformation controlling – depending on the level of attachments in the

closed loop of the servo-hydraulic connection provided for more testing machines

Two analogical and two digital channels, use for load cell or pressure transducer etc.

Standalone full automatic testing capacity

Can make manual tests if requested

A sample type and dimension can be entered with respect to the standards

Load-Time, Tensile-Time, Test Results and Sample reports observable and printable

RS232C (optional Ethernet) connection at 57600 band

One RS232 serial port for connecting either PC or printer for data transmission

Comes with Connection cable and software.

Large permanent memory up to 256 test results

Language select, English – Turkish

Can control two frames