Electrodynamic Fatigue Test Machines

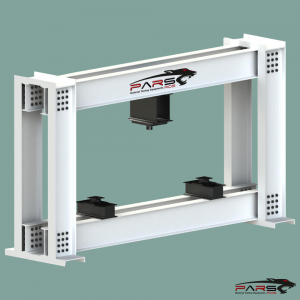

ParsRos Electrodynamic Fatigue Test Machines with force capacities up to 40 kN; With their clean and quiet designs, energy efficient electrodynamic fatigue

test devices are systems that can be designed to perform tests such as tensile tests, torsion tests, high-frequency fatigue tests, compression tests, bending tests, flexural tests.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

| Product Code | Product Description |

| PRS-EDFATMAC | Electrodynamic Fatigue Test Machines |

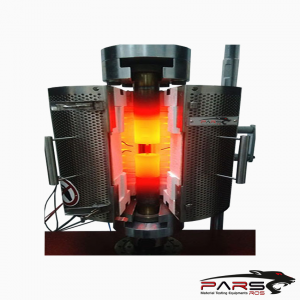

Electrodynamic Fatigue Test Machines

STANDARDS : ISO 10113, ISO 7206-4, ISO 7206-6, ASTM F543, ISO 14801, ISO 527-3, ASTM D882, ASTM F2077

ParsRos Electrodynamic Fatigue Test Machines with force capacities up to 40 kN; With their clean and quiet designs, energy efficient electrodynamic fatigue

test devices are systems that can be designed to perform tests such as tensile tests, torsion tests, high-frequency fatigue tests, compression tests, bending tests,

flexural tests.

ParsRos Electrodynamic Fatigue Test Machines are compatible with ParsRos accessories and can be configured to suit your different testing needs.

Test Samples

Polymers (elastomers, elastomers, plastics, polymers, rubber), Biomaterials and Medical Devices, Composites (carbon fiber, ceramic matrix, metal matrix, polymer

matrix),

Ceramics, Packaging Products, Microelectronic Materials

Applications

Polymers Fatigue Tests

Elastomeric Materials Fatigue Tests

Plastics Fatigue Tests

Rubber Fatigue Tests

Biomaterials and Medical Devices Fatigue Tests

Composites Fatigue Tests

Carbon fiber Fatigue Tests

Ceramic matrix Fatigue Tests

Metal matrix Fatigue Tests

Polymer matrix Fatigue Tests

Ceramic Fatigue Tests

Consumer Products and Packaging Fatigue Tests

Microelectronic Materials Fatigue Tests

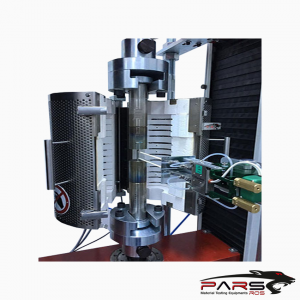

ParsRos Electrodynamic Fatigue Test Machines; Thanks to the DOLI electronic controller, it can automatically recognize and calibrate sensors such as load cells,

temperature sensors, LVDTs, strain gauges, I/Os, elongation measurement sensors and vibration sensors.

With the software of electrodynamic fatigue testing machines, real-time load, displacement, deformation, time and other parameters defined by the external user

can be presented with the test software, viewed graphically and all these data can be transferred to the graphic axes.

It has an overload protection system and has an automatic break detection system.

User defined methods can be created. It is possible to create 30 user-defined formulas and/or parameters based on force, displacement and deformation.

This number can be increased with additional modules. These parameters are recognized and reported both during the test control and at the end of the test.

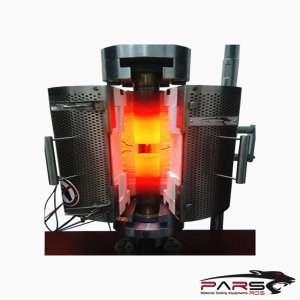

They are suitable systems for high frequency and high cycle fatigue tests with different amplitude values at frequencies up to 200 Hz.

Our electrodynamic fatigue testers are driven by linear motor technology. Friction, wear, etc. in the system.

Since problems will not occur, it can easily perform fatigue tests that take days or even months at high frequencies with the most precision.

Electrodynamic actuators with linear motors

Reviews (0)

Be the first to review “Electrodynamic Fatigue Test Machines” Cancel reply

You must be logged in to post a review.

TECHNICAL SPECIFICATIONS

FOR HIGH DYNAMIC APPLICATIONS WITH EXCEPTIONAL PERFORMANCES

Frequencies up to 150 Hz in force or displacement control

Suitable for high dynamic: accelerations up to 10g

Maximum load up to 40 Kn

Velocity up to 2.0 m/s

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Reviews

There are no reviews yet.