Electromechanical Torsion Test Machines

Electromechanical Torsion Test Machines are designed for determining of specification the torsional behavior.

The Machines can be manufactured as different torque capacities.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

Description

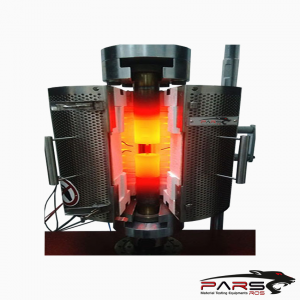

Electromechanical Torsion Test Machines

Electromechanical Torsion Test Machines are designed for determining of specification the torsional behavior.

The Machines can be manufactured as different torque capacities.

Software measures torque, angle, moment initially. As a result, software calculates maximum torque, breaking angle, breaking force, return numbers.

Turning angles are changeable according to standards.

The electromechanic driving is provided by high precision control unit and closed loop servo control.

Dual linear slide design offers high-torsional stiffness and low-axial friction

Adjustable crosshead locking system allows crosshead to be free-floating or fixed

Torque sernsors available from 0.2 – 1000 N-m (2 – 2,000 lbf-in) provide superior accuracy and zeroing capability (higher torque capacities available upon request)

Comprehensive torsion testing software provides graphical data plots and performs a wide range of calculations on torque and angle data

Torque cell protection device prevents damage to low-capacity torque cells during test setup

Safety enclosure with interlocks protects the operator from the rotating drive by preventing testing when the guard is open

TECHNICAL SPECIFICATIONS

Software Capable For

Allows real time data/graph plotting,

Allows real time control/change of variables,

Has a sevurity feature such as overvoltage, overtorque, overcurrent limits

Enables user to capture and extract all data in a raw and pdf format,

Allows user to run mixed mode control,

Fast data transfer of logged information to a PC at a rate of up to at least 1 kHz on all channels,

Capable for manual movement with RMC

Software Capable for applying

Torque controlled Test

Angle controlled Tests

Allows users to code custom calculations for both axes.