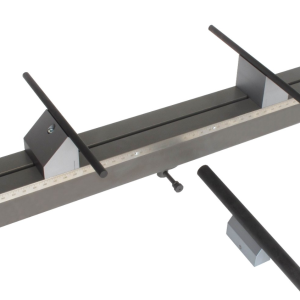

EN 12003 Test Fixture

EN 12003 specifies the test method to be used to determine the shear adhesion strength of reaction resin ceramic tile adhesives.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

EN 12003 – Determination of Shear Adhesion Strength of Reaction Resin Adhesives

EN 12003 specifies the test method to be used to determine the shear adhesion strength of reaction resin ceramic tile adhesives.

This Standard is applicable to all reaction resin ceramic tile adhesives for internal and external tile installations on floors and walls.

This European Standard does not contain performance requirements or recommendations for the design and installation of ceramic tiles.

NOTE: Ceramic tile adhesives can also be used for other kinds of tiles (natural and agglomerated stones, etc. ), where these do not adversely affect the stones.

EN 12003 / Subject Matter and Scope

Test method for determining the shear adhesion strength of reaction resin adhesives used in the installation of ceramic tiles and other compatible modular rigid

materials, in every type of application (floorings, coverings, indoors and outdoors).

EN 12003 / Material

Ceramic tiles: Type V2 [BIa UGL, with water absorption capacity E ≤ 0.2%, with flat bonding surface and dimensions of 100×100 mm]

Template made of non-absorbent material (polytetrafluoroethylene, PTFE) for the application of adhesive by points, with the geometry of the figure

Spacing rods with a diameter of (0.8±0.1) mm, for controlling the thickness of the adhesive applied

97×97 mm slab capable of exerting a force of (70±0.15) N

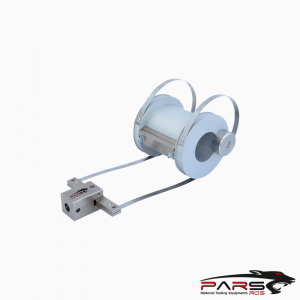

Machine for applying gradual force at constant speed, for coupling with the shearing device, either by horizontal pulling or vertical compression

EN 12003 / Procedure

After preparing the adhesive according to the instructions of the manufacturer and applying it to the rear of a V2 tile using the template, the spacers are placed

and a second tile is attached to the rear of the first tile. For 3 min. a load is applied to the assembly using the 70 N slab.

*** Ten test specimens are prepared and kept under laboratory conditions for 7 days.

After this time, the shear adhesion strength tests are performed:

► Initial bonding force: the force at the time of breakage is measured, after exerting a gradual force which causes the shearing equipment to move by 5 mm/min.

► Bonding strength after immersion in water: The test is carried out after keeping the ten test specimens submerged in water at (23±2) ºC for 21 days

► Bonding strength after thermal shocks: After subjecting the ten test specimens to four cycles of immersion in water at (23±2) ºC for 30 min and in water at 100 ºC

for another 30 min, they are allowed to cool for one last time to 23 ºC during 30 min. before performing the test.

Expression of Results

In every case, the shear adhesion strength is obtained by dividing the force measured at the time of breakage by the surface area of the tile in contact with

the adhesive (1,660 mm2 ).

The mean of the ten values obtained is calculated. Any values that deviate by ±20% from the mean value are discarded.

If five or more values remain, the mean is calculated again, producing the final result. If fewer than five values remain, the test must be repeated.

*** Before conducting EN 12003 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations