EN 12090 Test Fikstürü

EN 12090 specifies the equipment and procedures for determining shear behaviour. It is applicable to thermal insulating products.

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- Değerlendirmeler (0)

- TEKNİK ÖZELLİKLER

Açıklama

EN 12090 Thermal Insulating Products for Building Applications – Determination of Shear Behaviour

EN 12090 specifies the equipment and procedures for determining shear behaviour. It is applicable to thermal insulating products.

NOTE : The tests described in this standard do not determine pure shear behaviour, but measure the effects of applying two opposite parallel forces to

the major faces of the test specimen.

The test is however called shear in this text by convention.

The application of a force tangentially to the major surface of the test specimen is considered to represent more closely the stresses imposed upon thermal insulation

products in many building applications, particularly walls, than other methods of measuring shear performance e.g. bending tests

EN 12090 – Principle

A test specimen is subjected to a shear stress transmitted to the test specimen through rigid supports to which it is bonded.

The corresponding force-displacement curve is determined.

NOTE : Tests carried out using the single test specimen method have produced results for shear strength, which indicate the result to be dependent upon test

specimen thickness, with more scattered results at greater thicknesses.

Tests using the double test specimen method have also shown test specimen thickness to influence results for shear strength

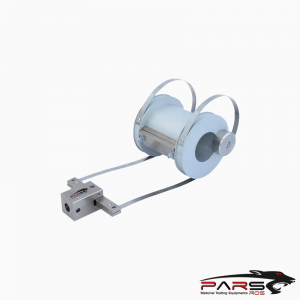

EN 12090 Apparatus

Test machine

General test machine capable of applying a sufficient force within the maximum displacement experienced in the shear test.

It shall be capable of operating at a constant rate of movement of the movable head of (3 ± 0,5) mm/min in a direction parallel to the longitudinal axis

of the test specimen assembly.

The test machine shall exert a force F on the test specimen with a maximum error of 1 %, and produce a displacement γ, of the movable support relative to

the fixed supports, having a maximum error of 1 %.

If the shear modulus is required, the force F and the displacement γ shall be simultaneously recorded to provide the curve of F, γ required in Clause 7.

It may be necessary to use a displacement transducer for accurate measurement of deformation particularly where a thick adhesive layer has been used in

preparing the test specimen.

The null or zero displacement of the test specimen may be calculated by subtraction from γ, the displacement due to the equipment and the same thickness of

adhesive measured without the test specimen, e.g. replace the test specimen by metal block(s) in a blank test.

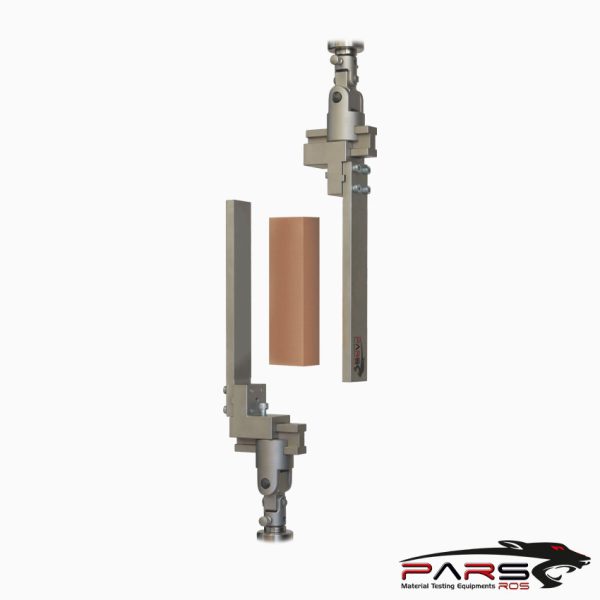

EN 12090 – Double Test Specimen Arrangement

The test machine shall exert longitudinal shear forces through parallel plates bonded to a double test specimen

The parallel plates shall be rigid with the outer plates attached to the fixed and the central plate to the movable parts of the test machine.

EN 12090 – Specimen supports

Single Test Specimen Assembly

Two flat rigid specimen supports of length 330 mm and width 50 mm which shall be attached to the grips of the test machine via an adaptor and universal joint.

The method of attaching the specimen supports to the grips

The thickness of the adaptors that connect the specimen supports to the test machine grips shall be the same as the thickness of the test specimen.

Flat rectangular sectioned mild steel plates with a thickness of 16 mm have proved suitable for the support material.

Double Test Specimen Assembly

The essential features are three flat rigid supports of which two can be maintained with their planes parallel and vertical.

Experience gained using both the single and double test specimen methods with several products indicated that it is of paramount importance that the specimen

supports are very rigid.

With the double test specimen arrangement, the fixed supports should be maintained in parallel vertical planes.

Bir yanıt yazın

Yorum yapabilmek için oturum açmalısınız.