EN ISO 898-1 Test Fikstürü

EN ISO 898-1 specifies mechanical and physical properties of bolts, screws and studs made of carbon steel and alloy steel when tested at an ambient temperature

range of 10 °C to 35 °C.

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- TEKNİK ÖZELLİKLER

Açıklama

Açıklama

EN ISO 898-1 Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel

Part 1:

Bolts, Screws and Studs with Specified Property Classes — Coarse Thread and Fine Pitch Thread

EN ISO 898-1 specifies mechanical and physical properties of bolts, screws and studs made of carbon steel and alloy steel when tested at an ambient temperature

range of 10 °C to 35 °C.

Fasteners — the term used when bolts, screws and studs are considered all together — that conform to the requirements of this part of ISO 898 are evaluated at that

ambient temperature range.

They might not retain the specified mechanical and physical properties at elevated temperatures (see Annex B) and/or lower temperatures.

NOTE 1 Fasteners conforming to the requirements of this part of ISO 898 are used in applications ranging from −50 °C to +150 °C.

Users are advised to consult an experienced fastener metallurgist for temperatures outside the range of −50 °C to +150 °C and up to a maximum temperature of

+300 °C when determining appropriate choices for a given application.

NOTE 2 Information for the selection and application of steels for use at lower and elevated temperatures is given, for example, in EN 10269, ASTM F2281 and in

ASTM A 320/A 320M.

Certain fasteners might not fulfil the tensile or torsional requirements of this part of ISO 898-1 because the

geometry of their heads reduces the shear area in the head compared to the stress area in the thread.

These include fasteners having a low head, with or without external driving feature, a low round or cylindrical head with internal driving feature or a countersunk head

with internal driving feature

This part of EN ISO 898-1 is applicable to bolts, screws and studs

a) Made of carbon steel or alloy steel,

b) Having triangular ISO metric screw thread according to ISO 68-1,

c) With coarse pitch thread M1,6 to M39, and fine pitch thread M8×1 to M39×3,

d) With diameter/pitch combinations according to ISO 261 and ISO 262,

e) Having thread tolerances according to ISO 965-1, ISO 965-2 and ISO 965-4.

It is not applicable to set screws and similar threaded fasteners not under tensile stresses (see ISO 898-5).

It does not specify requirements for such properties as

Weldability,

Corrosion resistance,

Resistance to shear stress,

Torque/clamp force performance, or

Fatigue resistance.

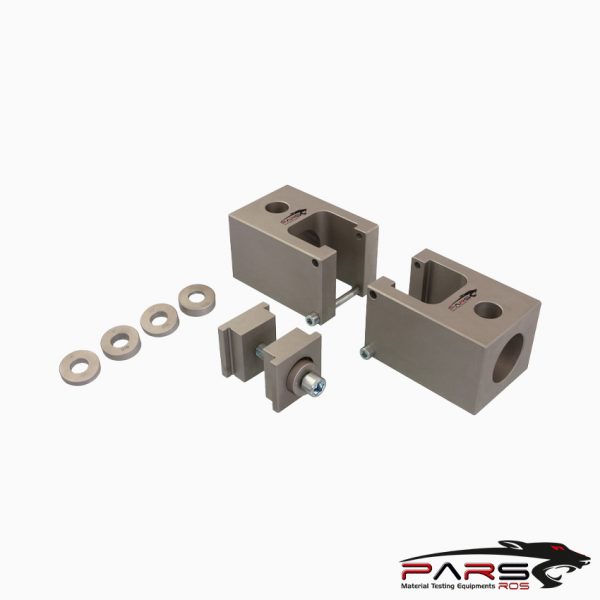

Apparatus

The tensile testing machine shall be in accordance with ISO 7500-1. Self-aligning grips shall not be used.

The testing device should be sufficiently rigid to ensure that bending occurs in the transition section between the head and the unthreaded shank or the thread.

Testing Device

The grips, the wedge and the adaptors shall be according to the following:

Hardness of 45 HRC min;

Thread tolerance class of the internally threaded adaptor

Hole diameter, dh,

Wedge

*** Before conducting EN ISO 898-1 it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.