ISO 1352 – Torque Controlled Fatigue Testing of Metallic Materials

ISO 1352 specifies the conditions for performing torsional, constant-amplitude, nominally elastic stress fatigue tests on metallic specimens without deliberately

introducing stress concentrations.

Bilgi Almak İçin Lütfen Bizimle İletişime Geçiniz

- Açıklama

- TEKNİK ÖZELLİKLER

Açıklama

Açıklama

ISO 1352 – Torque Controlled Fatigue Testing of Metallic Materials

ISO 1352 specifies the conditions for performing torsional, constant-amplitude, nominally elastic stress fatigue tests on metallic specimens without deliberately

introducing stress concentrations. The tests are carried out at ambient temperature.

ISO 1352 – Testing machine

The tests shall be carried out on a testing machine having a clockwise/anticlockwise (counter-clockwise) torsional loading capability, with smooth start and

no backlash when passing through zero.

The test start settings shall allow the required level to be reached without any overload.

The time frame for reaching the required level should be as short as reasonably possible.

ISO 1352 – Principle of test

Nominally identical specimens are mounted on a torsional fatigue testing machine and subjected to the loading condition required to introduce cycles of torsional

stress.

Any one of the types of cyclic stress illustrated in Figure 1 may be used. The test waveform shall be constant-amplitude sinusoidal, unless otherwise specified.

In an axially symmetrical specimen, change of mean torque does not introduce a different type of stress system and mean stress in torsion may always be regarded

as positive in sign.

The torque is applied to the specimen about the longitudinal axis passing through the centroid of the cross-section.

The test is continued until the specimen fails or until a predetermined number of stress cycles has been exceeded.

Cracks produced from torsional fatigue testing may be parallel to the longitudinal axis of the specimen, perpendicular to the longitudinal axis or at any angle between these two.

Tests shall be conducted at ambient temperature (ideally between 10 °C and 35 °C) unless otherwise agreed with the customer.

*** Before conducting ISO 1352 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

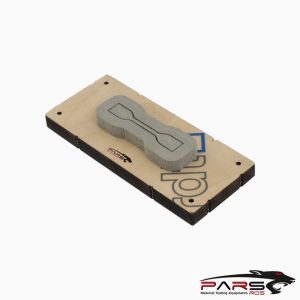

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.