ISO 15310 – In-Plane Shear Modulus by The Plate Twist Method of Fibre-Reinforced Plastic Composite

ISO 15310 specifies a method for determining the flat shear modulus (G12) of fiber reinforced plastic composites using a standard plate sample.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

Description

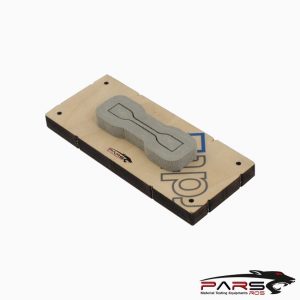

ISO 15310 – Determination of the In-Plane Shear Modulus by The Plate Twist Method of Fibre-Reinforced Plastic Composite

ISO 15310 specifies a method for determining the flat shear modulus (G12) of fiber reinforced plastic composites using a standard plate sample.

When applied to isotropic materials, the measured shear modulus is independent of the direction.

The method is used to determine the shear modulus of the test samples, but not to determine the shear strength.

It is applied to a plate resting on two points on a diagonal and loaded on the other diagonal by the simultaneous movement of two load points attached to a

transverse beam.

The method is suitable for use with fiber reinforced plastic composite materials with thermoplastic and thermoplastic matrices.

Because the shear strain is applied under bending conditions, for laminated materials with different fiber formats and / or different orientations, the layers of

material must be well distributed across the section so that they are approximately “homogeneous” in the thickness direction.

The main axes of the material, if any, should be oriented perpendicular to the edges of the plate.

NOTE: This method can be applied to non-reinforced polymers and other materials (for example, metals, ceramics and composites of metallic matrix or ceramic).

For the material fabricated using unidirectional layers, the shear modulus obtained using a multidirectional specimen (ie, 0 ° / 90 ° / ± 45 °) is not the same as that

obtained for the unidirectional or crossover material (0 ° / 90 °).

*** Before conducting ISO 15310 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations