ISO 21182 Test Fixture

ISO 21182 specifies test methods for determining the dynamic and static coefficients of friction for light conveyor belts

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

Description

ISO 21182 Light Conveyor Belts — Determination of The Coefficient of Friction

ISO 21182 specifies test methods for determining the dynamic and static coefficients of friction for light conveyor belts

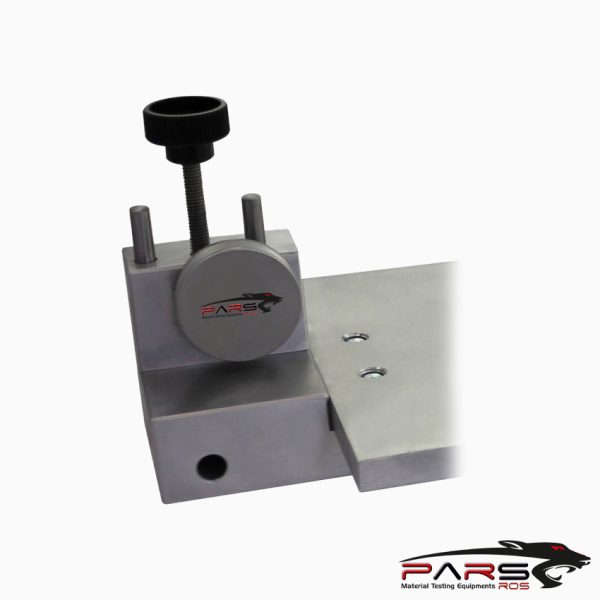

Apparatus

Testing table, onto which the test piece shall be clamped.

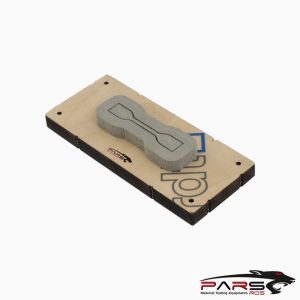

Metallic test panel, having the following dimensions:

Thickness, 0,8 mm;

Width, (76 ± 0,5) mm;

Length, 152 mm;

Testing area, (76 ± 0,5) mm × (131,5 ± 0,5) mm = (100 ± 1) cm2.

The test panel shall be made of steel, type CR1 according to ISO 3574:1999, with a hardness of between HRB 60 and HRB 70, with a milled surface and surface

roughness, Ra, 0,9 µm to 1,3 µm in accordance with ISO 4287.

Because the surface can change due to the abrasion of the test piece, the metallic test panel shall be replaced after a maximum of 50 applications, but after one

day of use at the latest.

Because the test panel is not stainless it shall be kept in its original pack in a dry place until first used.

The personnel handling the panel shall wear clean cotton gloves and touch the panel only at the edges.

Weight

Generating a normal force of 50 N ± 1 N together with the metallic test panel.

The weight shall be made of steel having a density of 7,85 g/cm3 and have the following dimensions:

Length, (120 ± 0,2) mm;

Width, (75 ± 0,2) mm;

Height, (71 ± 0,2) mm.

*** Before conducting ISO 21182 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations