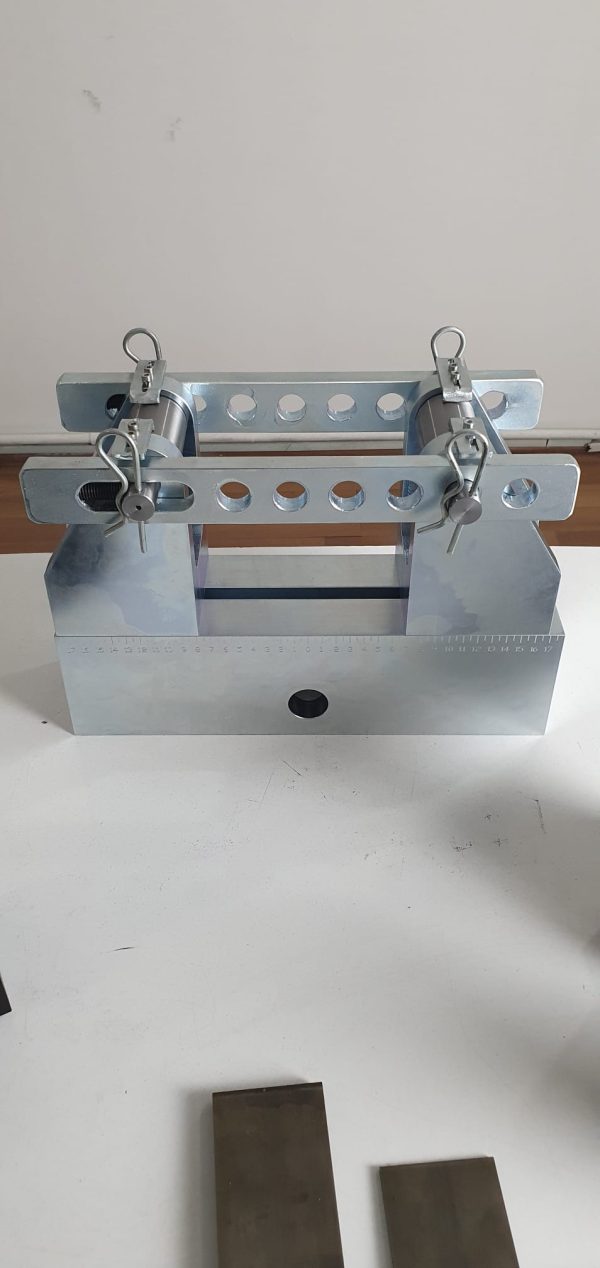

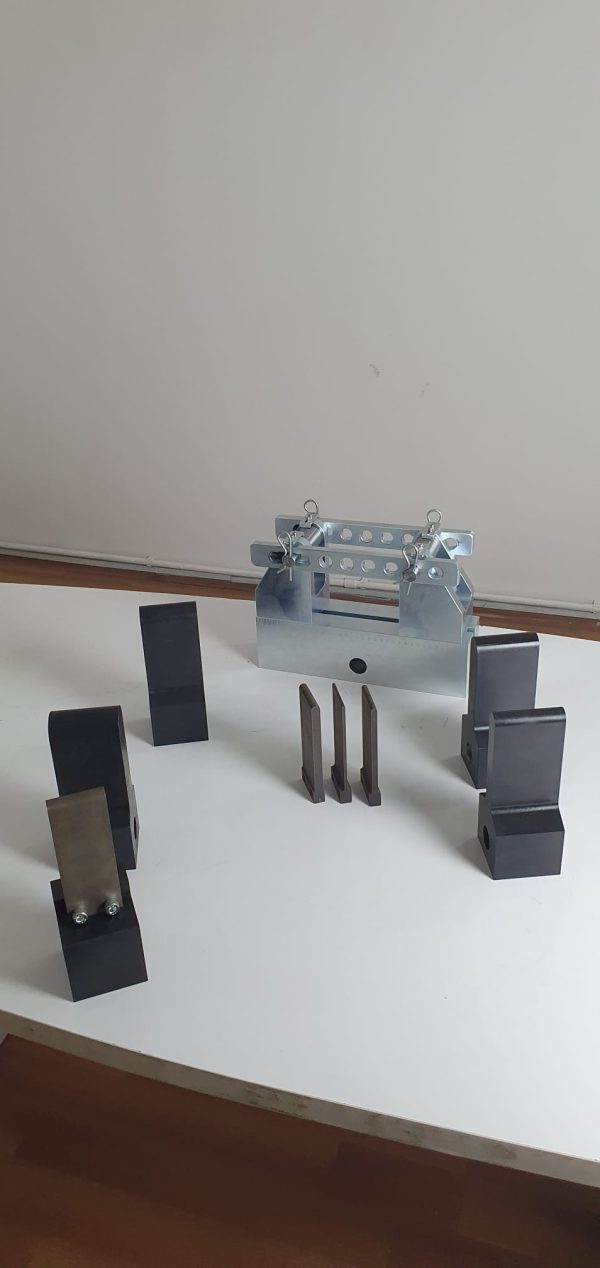

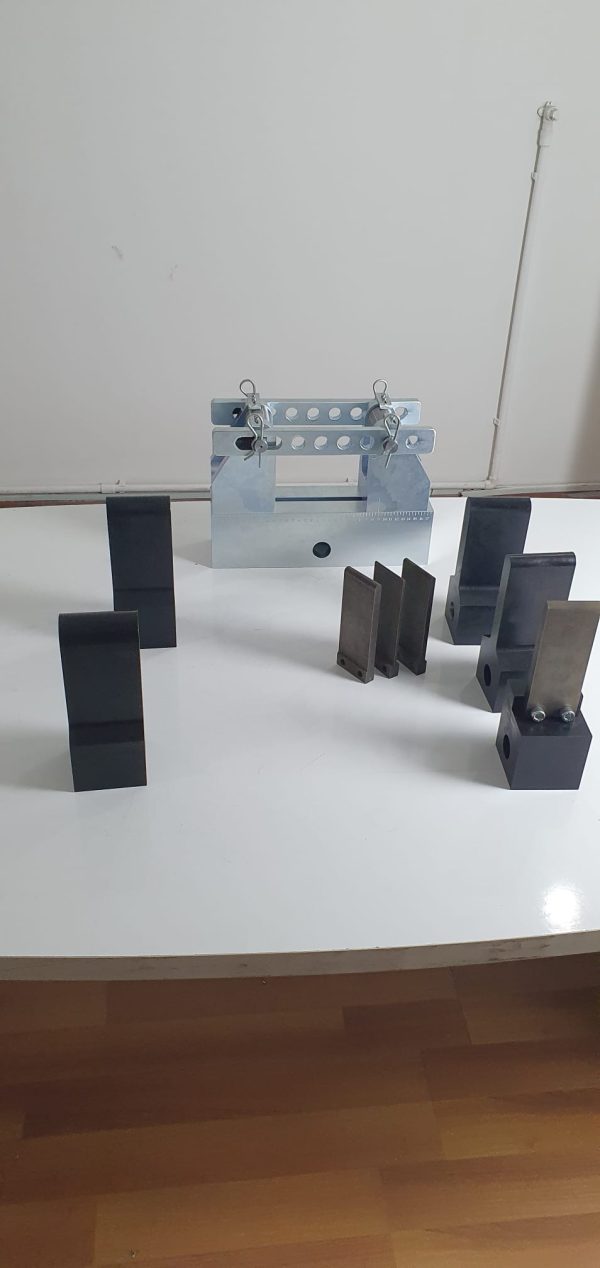

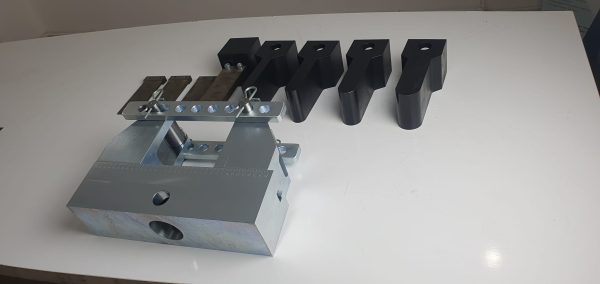

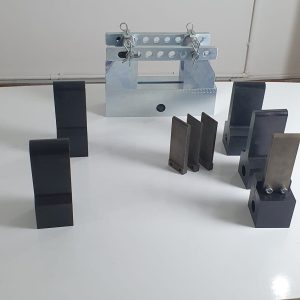

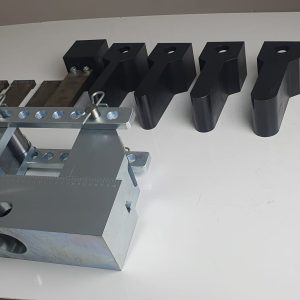

ISO 5173 Test Fixture

ISO 5173 specifies a method for making transverse root, face and side bend tests on test specimens taken from butt welds.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

Description

ISO 5173– Destructive Tests on Welds in Metallic Materials — Bend Tests

ISO 5173 specifies a method for making transverse root, face and side bend tests on test specimens taken from butt welds, butt welds with cladding

(subdivided into welds in clad plates and clad welds) and cladding without butt welds in order to assess ductility and/or absence of imperfections on or near to

the surface of the joint.

It also gives the dimensions of the test specimen. In addition this International Standard specifies a method for making longitudinal root and face bend tests

to be usedinstead of transverse bend tests for heterogeneous assemblies when base materials and/or filler metal have a significant difference in their physical

and mechanical properties in relation to bending.

This International Standard applies to metallic materials in all forms of product with welded joints made by any fusion arc welding process.

Side bend tests may be carried out when the wall thickness is greater than 12 mm.

Principle

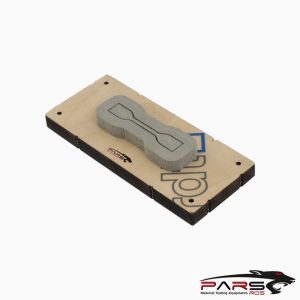

Submitting a test specimen, taken transversely or longitudinally from a welded joint, to plastic deformation by bending it, without reversing the bending direction,

in such a way that one of the surfaces or cross-sections of the welded joint is in tension.

Unless otherwise specified, the test shall be carried out at ambient temperature (23 5) °C.

The test shall be made in accordance with one of the methods described in clause 6.

Preparation of Test Specimens

General Specimens shall be prepared in such a manner that the preparation does not affect either the base material or the weld metal.

Location

For transverse bend testing of butt welds the test specimen shall be taken transversely from the welded joint of the manufactured product or from the

welded test piecein such a way that after machining the weld axis will remain in the centre of the test specimen or at a suitable position for testing.

For longitudinal bend testing of butt welds the test specimen shall be taken longitudinally from the welded joint of the manufactured product or from the

welded test piece.

The location and orientation of bend test specimens of cladding shall be specified by the application standard or by agreement between the contracting parties.

Marking

Each test piece shall be marked to identify its exact location in the manufactured product or in the joint from which it has been removed.

If required by the relevant application standard, the direction of working (e.g. rolling or extrusion) shall be marked.

Each test specimen shall be marked to identify its exact location in the test piece from which it has been removed.

When removed from the test piece, each test specimen shall be marked

*** Before conducting ISO 5173 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities

PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations