Manhole Cover Testing Machines

ParsRos Manhole Cover Testing Machines are designed for testing of steel fiber and reinforced, metal and composite manhole covers according to EN 1917, EN 124 and

EN 1433 standards.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

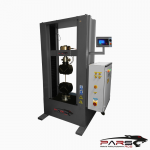

Manhole Cover Testing Machines

ParsRos Manhole Cover Testing Machines are designed for testing of steel fiber and reinforced, metal and composite manhole covers according to

EN 1917, EN 124 and EN 1433 standards.

Test systems; suitable for manhole covers of type A15, B125, C250, D400, E600, F900 tests and testers consists of a 4-column body and a double-stage actuator and

electronic power unit for capacities from 100 kN to 1500 kN.

The machines control is provided by PC controlled Electronic Controller .

Electronic Contoller ; has the appropriate test modules to perform the following tests:

Manhole Cover Compression Test

Manhole Cover Bending Test

Manhole Cover Permanent Set Test

Manhole Cover Removal Test (upon request, as optional)

Manhole Cover Tilt Test (upon request, as optional)

Manhole Cover Pull Off Test (upon request, as optional)

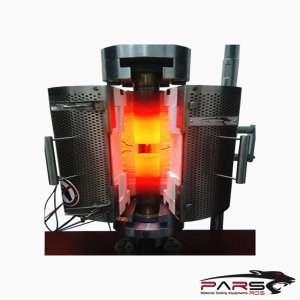

The system is equipped with Optical Sensor for the measurement of permanent seating tests. System is capable for cyclic loading tests and load constant loading tests at

adjustable test speeds.

Manhole Cover Testing Machines – Standard Compression, Bending and Crushing Tests

The sensors can be calibrated at unlimited points, thus enabling precise calibration.

Material Testing Software can detect 50 sensors. (LVDT, transducer, extensometer etc.)

Program and module devices (such as loadcell, transmitter, elongation scale, temperature sensor, encoder, extensometer) read the sensors precisely and transfer

them to the interface.

Program, pdf, excel, bmp formats can be reported.

Program graphs should provide graphs such as force-elongation, force-time, force-position, force-strain, or can be defined according to the sensor and formulas

requested by the user.

The desired unit can be defined according to the test device.

The program graph screen is capable of moving and zooming to examine the graph after the test is finished.

Formulas can be defined according to test requirements

Reviews (0)

Be the first to review “Manhole Cover Testing Machines”

You must be logged in to post a review.

TECHNICAL SPECIFICATIONS

| Force Capacities | kN | 100-1500 |

| Max.-Min. Test Speed | kN/s | 1-5 |

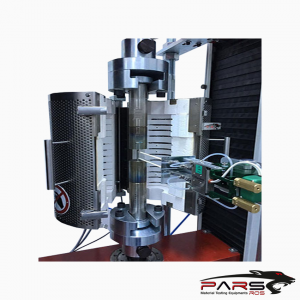

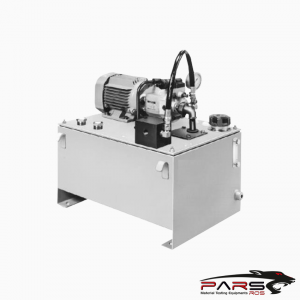

| Configurations | Four column rigid load frame, high precision load cell, adjustable piston, hydraulic power unit, electronic controller and testing software | |

| Piston Stroke | mm | 250 (higher is optional) |

| Load Measurement System | Class 1 according to ISO 7500-1 | |

| Drive | type | Servo Hydraulic |

| Position Measurement Resolution | mm | 0,001 |

| Strain measurement accuracy | % | 1 |

| Position measurement accuracy | µm | +/- 10 |

| Electric Requirement | 220 V 60 Hz (Mono Phase) | |

| Environmental Conditions | /+10 to +38°C (+50 to +100°F) / 10 to 90% | |

| Humidity/Non-condensing | ||

| Accesories | ||

| Compression Plates | ||

| 3 Point Bending Fixture ( Optional ) | ||

| LVDT (Optional) | ||

Reviews

There are no reviews yet.