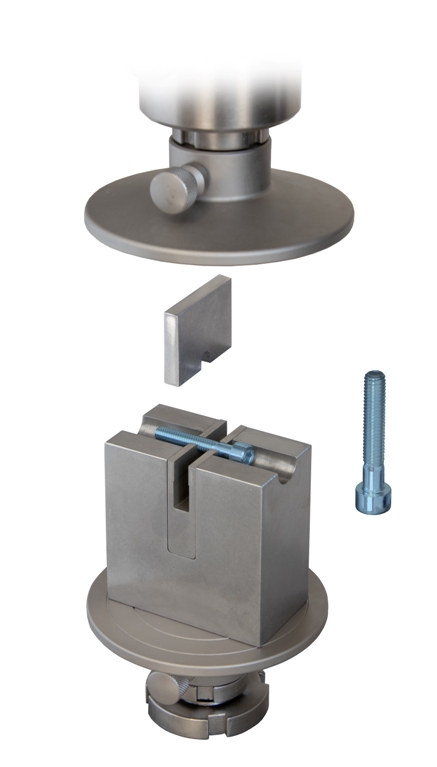

NASM 1312-13 Test Fixture

The Aerospace Industries Association publishes NASM 1312-13, Fastener Test Methods for Double Shear Tests.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

Description

NASM 1312-13, Fastener Test Methods for Double Shear Tests

The Aerospace Industries Association publishes NASM 1312-13, Fastener Test Methods for Double Shear Tests.

This standard is focused on the details surrounding double shear testing of fasteners. It also replaced MIL-STD-1312-13A.

The test described in this standard can be difficult because the test rate is specified in terms of stress and load, but the rate needs to remain constant throughout

the entire test.

In addition, total failure of the fastener is undesirable, so break detection and stopping machine movement is critical.

*** Before conducting NASM 1312-13 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

TECHNICAL SPECIFICATIONS

Max. specimen diameter : 6.3 mm

Steel, nickel-plated, hardened

Compression platens are not included in the scope of delivery and should be ordered seperately

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations