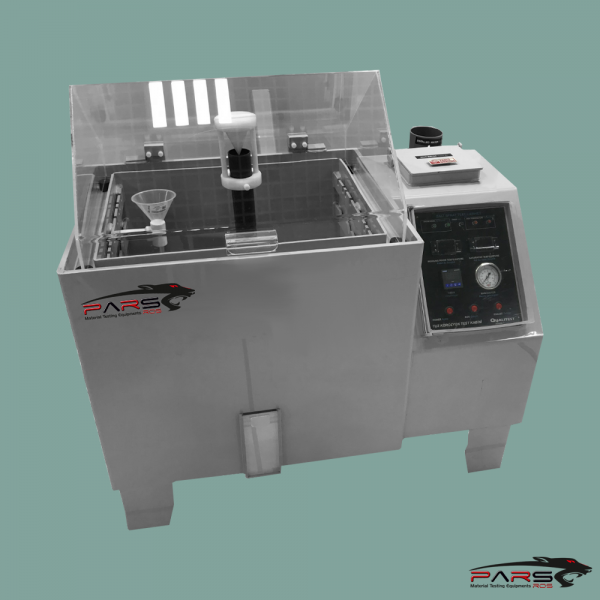

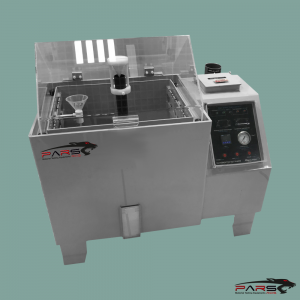

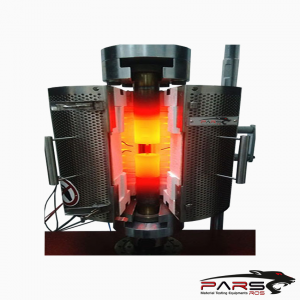

Salt Spray Test Cabinet

Salt Spray Test Cabinet has a standardized test method to check corrosion resistence of coated samples.

Salt spray test is an accelerated corrosion test that produces a corrosive attack to the coated samples in order to predict its suitability in use as a protective finish.

Please Contact With Us For More Information

- Description

- TECHNICAL SPECIFICATIONS

Description

| Product Code | Product Description |

| PRS-USCORT | Salt Spray Test Cabinet |

Salt Spray Test Cabinet

Salt Spray Test Cabinet has a standardized test method to check corrosion resistence of coated samples.

Salt spray test is an accelerated corrosion test that produces a corrosive attack to the coated samples in order to predict its suitability in use as a protective finish.

This standard salt spray test machine (corrosion resistance test chamber) is the surface treatment for various materials, including paint, electroplating, inorganic

film, anode handling, anti-rust oil, anti-corrosion treatment to test

The appearance of corrosion products (oxides) is evaluated after a period of time.

Test duration depends on the corrosion resistance of the coating; the more corrosion resistant the coating is, the longer the period in testing without showing signs of

corrosion.

Different coatings have different behaviour in salt spray test and consequently, test duration will differ from one type of coating to another.

Characters

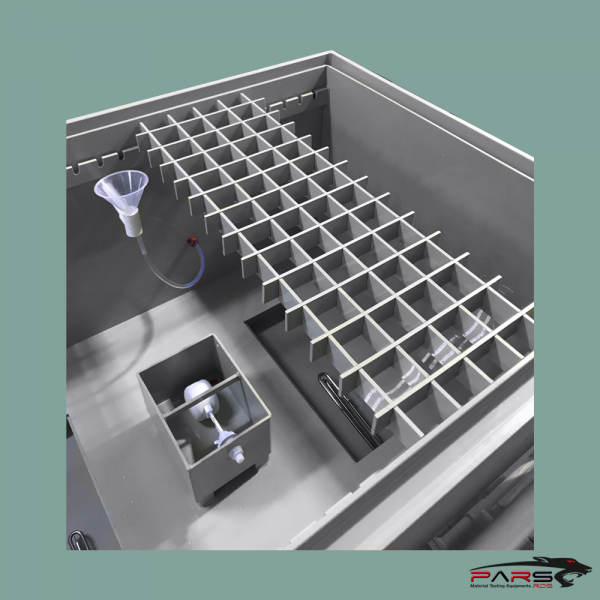

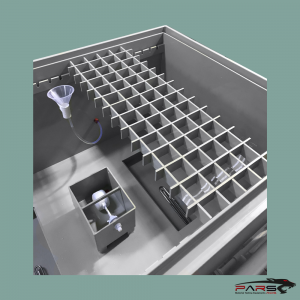

The spray nozzle the heart of tester adopt Be Nute Principle which change saline water into atomization but no crystallization produced.

The controller is digital type microcomputer which delivers precision temparature

Parameters show on the display screen such as temparature, humidity, pressure, spray capacity and time.

Test specifications are accepted worldwide.

Dimensions: Optional ( 150 , 400 , 750 , 1600 , …. )

Complies with ISO 9227, ASTM-B 117, JIS-D020, H8502, H8610, K5400, Z2371 standards.

Solution (Salt water) and pure water cover integrated in the device,

Transparent visible inside

Automatic warning system when water is low

Corrosion resistant Polypropylene body,

Plastic Hinged Plexiglass Transparent Top Cover

Water Warning Alarm System for Resistance Protection Purpose

Integrated Brine Tank.

Integrated Pure Water Tank (Pure water must have level indicator.)

Digital Display Inside Cabin and Air Temperature Setting

Temperature range: room temperature: + 10C —- + 55C

Air Tank temperature range: + 10C —- + 60C

“Alarm Temperature

Safety temperature control system with double thermocouples

Time Setting 0-9999 (hour, minute, second)

Pressure Gauge: 0 – 6 Bar

Temperature stability: ± 2C

Temperature variation: ± 1.0C

Air Pressure: 86 — 106Kpa.

Structure material F.R.P

Accessories test salt, barrel, tool

Salt spray amount: 1—10 ml / 80cm2.h (adjustable)

Spray methods: fixed (fixed)

Electric power: 220V / 50Hz

CE Production Certificate

Spare Parts Drawer (for 400L and above cabinets)

Pneumatic Cover System (750L and above cabins)